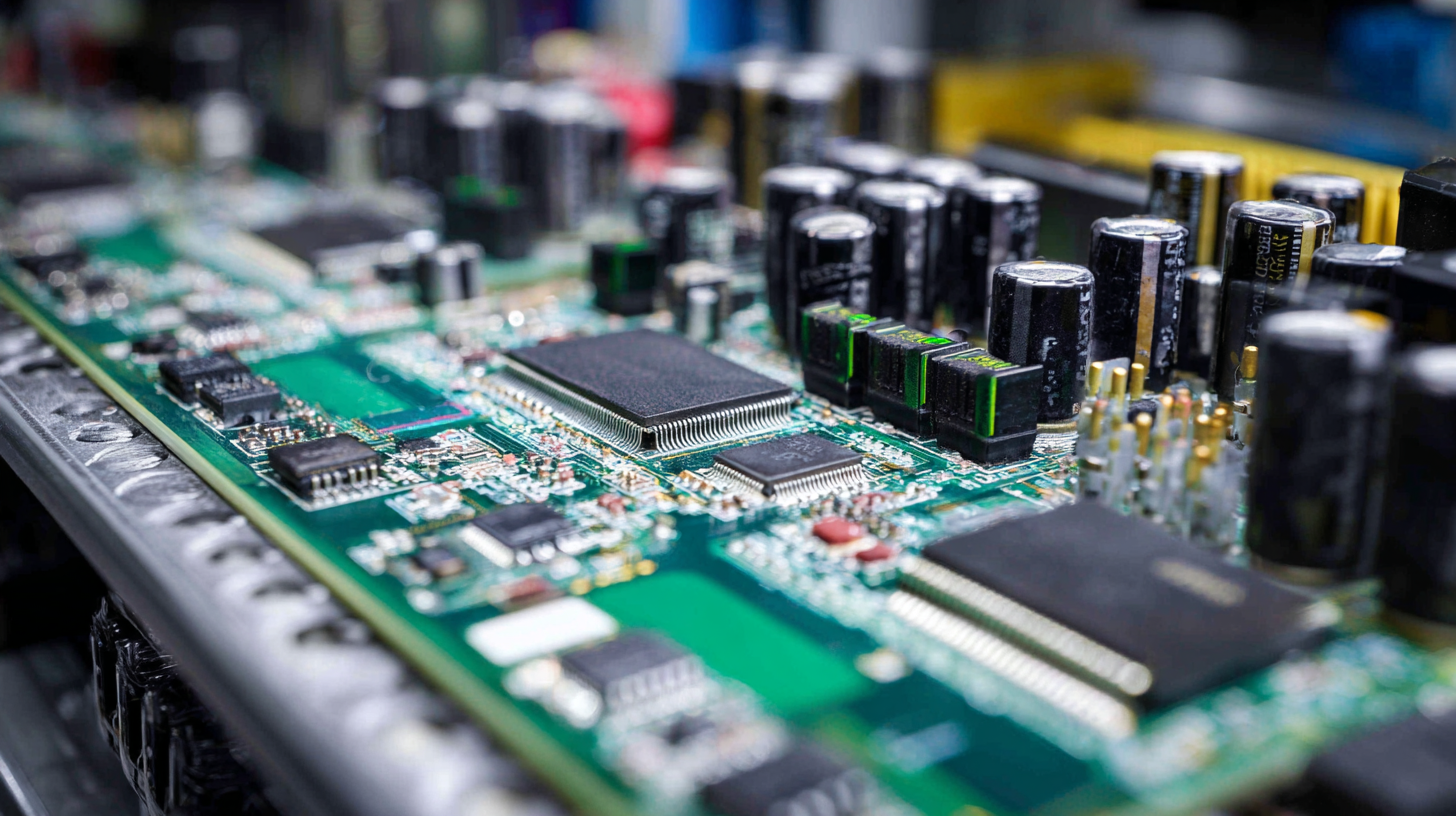

The electronic industry is undergoing significant transformation, driven by rapid advancements in technology and increasing demand for more efficient solutions. As we look toward 2025, innovations in PCB manufacturing and assembly are at the forefront of these changes, enabling the production of smaller, lighter, and more complex devices that cater to the ever-evolving requirements of consumers and industries alike. According to a recent report by Markets and Markets, the global PCB market is projected to reach $80 billion by 2025, with a compound annual growth rate (CAGR) of 4.5%. This growth is largely attributed to the rise of IoT, wearable technology, and electric vehicles, which are placing new demands on traditional manufacturing processes.

In this context, understanding how to optimize PCB manufacturing and assembly processes will be crucial for companies looking to stay competitive. Innovations such as automation, advanced materials, and enhanced design software are reshaping the landscape, allowing for greater efficiency and precision. Furthermore, a report by Statista highlights that the adoption of smart manufacturing technologies is expected to reduce production costs by up to 30%. As these trends continue to evolve, businesses must adopt best practices and leverage cutting-edge technologies to meet industry standards and customer expectations effectively. In this article, we will explore the top innovations in PCB manufacturing and assembly set to transform the electronics landscape by 2025.

The evolution of printed circuit boards (PCBs) is heavily influenced by the development of innovative materials that enhance performance and reliability. As we approach 2025, the electronics industry is set to witness a significant transformation with advanced substrates that promise better thermal management, reduced weight, and improved signal integrity. These materials, such as polyimide and advanced ceramic composites, offer exceptional dielectric properties, enabling higher component densities and faster signal speeds, crucial for modern electronic applications.

Additionally, the integration of sustainable materials into PCB manufacturing is becoming increasingly important. Bio-based resins and recycled substrates not only contribute to environmental sustainability but also demonstrate comparable performance to traditional materials. This shift not only aligns with global sustainability goals but also meets the growing demand for eco-friendly solutions in the electronics market. As manufacturers embrace these innovations, the potential for creating high-performance, robust PCBs increases, allowing for the next generation of electronic devices to thrive in a rapidly evolving technological landscape.

The role of artificial intelligence (AI) in PCB design automation is becoming increasingly prominent as the electronics industry seeks to streamline manufacturing processes and enhance efficiency. According to a report by Technavio, the global PCB market is projected to grow at a CAGR of 4.4% from 2021 to 2025, with automation playing a crucial role in meeting this demand. AI technologies are being integrated into PCB design software, allowing engineers to leverage machine learning algorithms to optimize layouts, reduce design errors, and accelerate the time-to-market for new products.

AI's capabilities extend beyond design optimization; it also facilitates real-time data analysis throughout the manufacturing process. As stated in a market research report by Gartner, companies adopting AI in manufacturing can expect a productivity increase of up to 20%. By utilizing predictive analytics, PCB manufacturers can anticipate potential production issues, leading to reduced downtime and waste. The combination of AI-driven design automation and advanced manufacturing techniques positions the electronics industry for significant advancements, ensuring more reliable, efficient, and cost-effective PCB production as we approach 2025.

As the electronics industry continues to evolve, miniaturization remains a pivotal trend influencing PCB (Printed Circuit Board) manufacturing and assembly. The shift towards smaller components is driven by the demand for more compact and efficient electronic devices. This trend not only enhances portability but also enables the integration of advanced functionalities within constrained spaces. However, miniaturization presents challenges in PCB assembly and reliability, making it crucial to adopt innovative strategies in manufacturing processes.

To successfully navigate the complexities of miniaturized components, manufacturers should focus on enhancing precision during assembly. Techniques such as selective soldering and advanced placement technologies can significantly improve the accuracy of component placement, thereby reducing the likelihood of defects.

Tips:

The electronics industry is on the brink of a significant transformation as additive manufacturing techniques redefine PCB production. Traditionally dominated by subtractive methods, PCB manufacturing is experiencing a shift towards additive processes, which enable more complex designs and reduce material waste. Techniques such as 3D printing allow for rapid prototyping and smaller batch sizes, making it feasible for companies to innovate at a pace previously thought unattainable. Brands can now iterate designs more efficiently, testing and implementing custom features tailored to specific applications.

Additionally, the adoption of additive manufacturing enhances design flexibility, allowing engineers to explore creative layouts that were constrained by traditional manufacturing methods. This advancement opens the door to producing multi-layered PCBs with intricate geometries, optimized for performance in compact electronic devices. By facilitating the integration of components directly into the substrate, additive techniques can also contribute to the miniaturization of electronic devices, a crucial factor in the ever-evolving landscape of consumer electronics. As these innovations gain traction, the potential for more sustainable production practices and reduced lead times is becoming increasingly evident in the PCB manufacturing landscape.

| Innovation | Description | Impact on Production | Adoption Rate (%) |

|---|---|---|---|

| Additive Manufacturing | Utilizing 3D printing to create complex PCB designs. | Reduces material waste and allows for customization. | 30 |

| Integrated Circuit Embedding | Embedding ICs directly into the PCB layers. | Improves space efficiency and performance. | 25 |

| Flexible PCBs | PCBs that can bend and flex without breaking. | Ideal for wearable tech and compact devices. | 40 |

| Automated Optical Inspection (AOI) | Using machines to inspect PCBs for defects. | Increases accuracy in quality control. | 50 |

| High-Density Interconnect (HDI) Technology | Layers of circuits with fine lines and small pads. | Facilitates the miniaturization of electronics. | 35 |

| Bio-based Materials | Using sustainable materials for PCB production. | Reduces environmental impact. | 20 |

In 2025, the electronics industry is poised to undergo significant transformations with a focus on sustainability in PCB production. The implementation of green practices in PCB manufacturing not only aims to reduce environmental impact but also seeks to meet the growing demand for eco-friendly products from consumers and regulators alike. Companies are increasingly adopting techniques such as using biodegradable materials, reducing energy consumption, and minimizing waste throughout the manufacturing process. These innovations not only align with environmental goals but also enhance the efficiency and longevity of electronic products.

Furthermore, advancements in recycling technologies are expected to play a crucial role in sustainability efforts. Manufacturers are exploring closed-loop systems that allow for the reuse of materials from outdated PCBs, thereby reducing the reliance on virgin resources. Additionally, the push for circular economy principles encourages collaboration across the supply chain, fostering partnerships that prioritize eco-friendly practices. As the electronics industry moves towards 2025, the integration of these green practices will not only redefine PCB production but will also set new standards for sustainability across the sector.