In the fast‑evolving world of electronics manufacturing, Surface Mount Technology (SMT) often gets the spotlight for its ability to produce compact, high‑density boards. However, in industries where mechanical strength, durability, and reliability are non‑negotiable, through‑hole assembly remains a critical choice. At YIC Assm, we understand that while newer technologies offer advantages, through‑hole assembly still plays a vital role—especially in rugged and industrial applications.

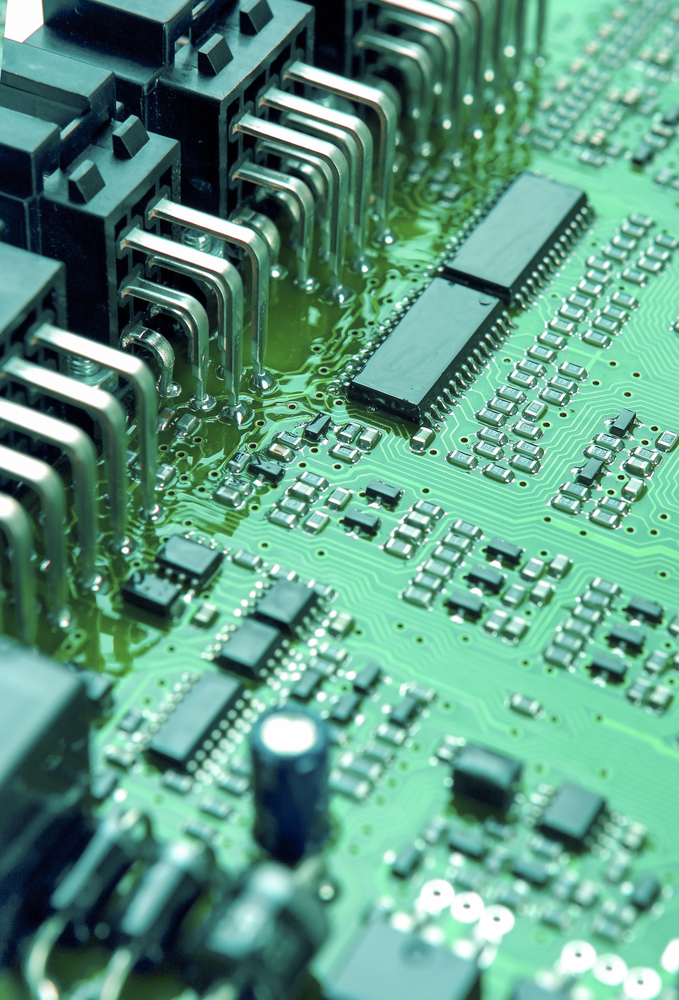

Through‑hole assembly involves inserting component leads through pre‑drilled holes in a printed circuit board (PCB) and soldering them in place on the opposite side. This creates strong mechanical bonds that can withstand significant physical stress, vibration, and extreme environmental conditions. That’s why through‑hole is often the preferred method for aerospace, defense, industrial machinery, automotive, and high‑reliability power systems.

One major advantage of through‑hole technology is its resistance to mechanical strain. In industrial environments, electronics may face constant movement, shock, or temperature fluctuations. Surface‑mounted components, while excellent for many applications, do not always provide the same level of durability under these conditions. Through‑hole components, anchored deep into the board, offer superior resistance to these stresses, ensuring a longer operational life.

Through‑hole assembly is also ideal for larger or heavier components such as transformers, large capacitors, connectors, and switches—parts that must remain securely in place even under heavy usage. This makes it essential for mission‑critical electronics where component failure is simply not an option.

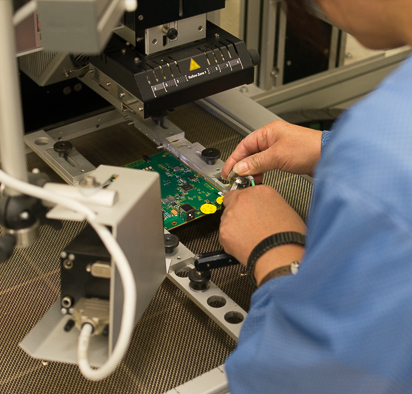

At YIC Assm, we specialize in both manual and automated through‑hole assembly, giving our customers flexibility based on their project requirements. Our skilled technicians handle everything from single‑sided and double‑sided PCBs to complex mixed‑technology builds that combine through‑hole and SMT. Every board undergoes thorough inspection to ensure solder joint integrity and adherence to IPC‑A‑610 standards.

While many modern devices rely solely on SMT, through‑hole technology continues to be the gold standard for ruggedized electronics. Whether you’re producing heavy‑duty control systems, industrial automation equipment, or aerospace electronics, through‑hole assembly provides the strength and reliability your products demand.

If you’re developing electronics for high‑stress environments, partnering with an experienced manufacturer like YIC Assm ensures your boards are built to last. Contact us today to learn more about our through‑hole assembly services and how they can strengthen your next project.