In today's rapidly evolving electronics landscape, the adoption of flexible printed circuit boards (flexible PCBs) has emerged as a game-changing technology that enhances design versatility and operational efficiency. According to a recent report by Markets and Markets, the global flexible PCB market is projected to reach USD 27.87 billion by 2027, growing at a CAGR of 15.2% from 2022. This growth is driven by the increasing demand for miniaturized devices in sectors such as consumer electronics, automotive, and medical equipment, where lightweight and compact designs are essential.

In today's rapidly evolving electronics landscape, the adoption of flexible printed circuit boards (flexible PCBs) has emerged as a game-changing technology that enhances design versatility and operational efficiency. According to a recent report by Markets and Markets, the global flexible PCB market is projected to reach USD 27.87 billion by 2027, growing at a CAGR of 15.2% from 2022. This growth is driven by the increasing demand for miniaturized devices in sectors such as consumer electronics, automotive, and medical equipment, where lightweight and compact designs are essential.

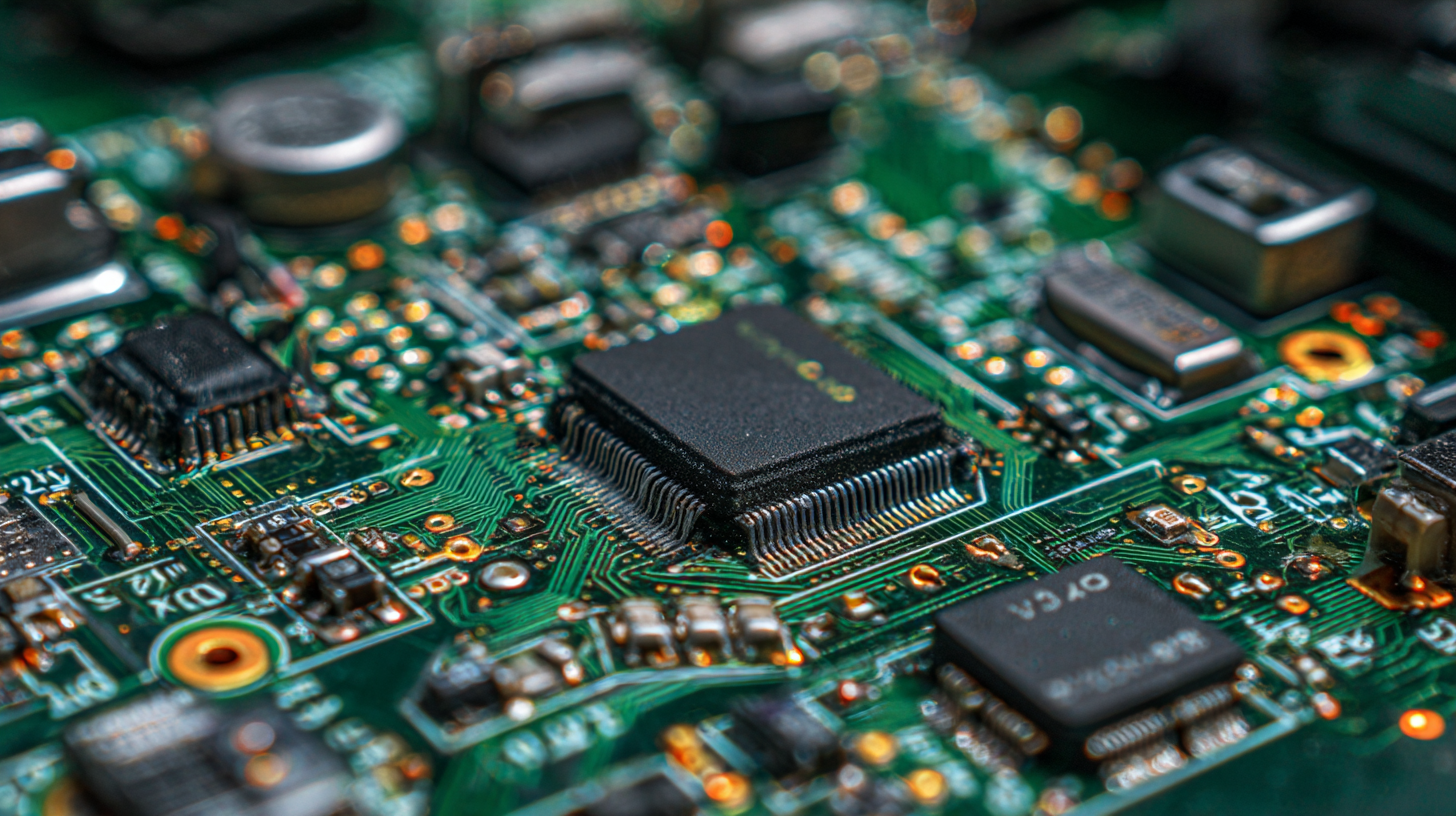

Flexible PCBs provide significant advantages over traditional rigid PCB designs, including their ability to bend, twist, and fold, which allows for innovative applications in tight spaces. The adoption of flexible PCBs not only contributes to weight reduction but also enhances thermal performance and reliability. As reported by Allied Market Research, the automotive sector alone is anticipated to experience a substantial shift towards flexible PCB technologies, accounting for over 30% of the market share by 2025. As industries continue to seek solutions that support advanced device functionality while optimizing space and performance, flexible PCBs stand as a critical element of modern electronics design.

The flexible printed circuit board (FPCB) industry is witnessing significant growth and transformation, driven by the increasing demand for compact and lightweight electronics. The global printed circuit board (PCB) market is projected to grow from $715.7 billion in 2024 to $1,134.9 billion by 2032, indicating a robust annual growth rate. This surge is fueled by advancements in technology and the rising integration of FPCBs in various applications, particularly within consumer electronics, automotive sectors, and smart devices.

In China, the FPCB market is evolving rapidly, reflecting broader trends in technology and market behavior. The industry's landscape showcases a dynamic supply-demand environment that adapts to innovations and shifting consumer preferences. Key factors include an expanding electronic consumer base and a push towards miniaturization, which drive manufacturers to seek efficient production processes and materials. As automotive technology advances with a focus on intelligent cockpit systems, flexible PCBs are becoming integral to achieving these sophisticated electronic designs, presenting both opportunities and challenges in this competitive arena.

Flexible PCBs (Printed Circuit Boards) have revolutionized modern electronics design, allowing for innovative solutions to complex challenges. One major advantage of flexible PCBs is their ability to fit into compact and intricate spaces, which is increasingly important as devices shrink in size. This flexibility not only enhances design efficiency but also contributes to lighter and more durable products, making them ideal for applications in consumer electronics, medical devices, and automotive technologies.

When designing with flexible PCBs, keep in mind that careful layout planning can significantly enhance performance. It’s crucial to manage bending radii to ensure reliability in dynamic applications. Additionally, using high-quality materials can optimize electrical performance while maintaining the flexibility needed for modern designs. Explore the integration of multilayer constructions that allow for more complex circuitry without compromising space or functionality.

Moreover, the growing trend towards wearables and IoT devices emphasizes the need for flexible, lightweight solutions. As market demand for these types of products continues to rise, understanding the full potential of flexible PCB technology will be essential. Consider leveraging simulation tools to predict performance under various conditions, which can save time and costs in the prototyping stages. Embracing these tips can unlock new design possibilities and drive innovation in your electronic products.

| Benefit | Description | Market Growth (%) |

|---|---|---|

| Space Saving | Flexible PCBs can be bent and twisted to fit compact spaces. | 15% |

| Weight Reduction | They are lighter than traditional PCBs, reducing overall device weight. | 10% |

| Design Flexibility | Allows for innovative shapes and layouts in designs. | 20% |

| Improved Reliability | Less prone to mechanical breakage in flexible applications. | 12% |

| Thermal Management | Better heat dissipation can enhance performance. | 18% |

| Reduced Assembly Costs | Less assembly time and fewer parts can lower costs. | 14% |

| Durability | More resistant to environmental stress and shock. | 11% |

| Enhanced Performance | Improved signal integrity for high-speed applications. | 16% |

| Easier Routing | More efficient routing options reduce design complexity. | 9% |

| Sustainability | Potentially lower environmental impact with fewer materials. | 13% |

Flexible PCBs (Printed Circuit Boards) have emerged as a vital component in modern electronics design, particularly due to their cost efficiency in manufacturing. By utilizing flexible materials, manufacturers can reduce the number of required components and simplify assembly processes. This reduction in complexity not only leads to lower labor costs but also diminishes the potential for assembly errors, thereby lowering the overall manufacturing expenditures. Furthermore, flexible PCBs allow for multi-layered designs in a compact form, enabling the integration of more functionality without a corresponding increase in size or cost.

In addition to direct cost savings, flexible PCBs also help manufacturers to optimize material usage. Traditional rigid PCBs often involve waste during production due to the cutting of standard board sizes. In contrast, flexible PCBs can be produced with minimal waste, as they can be designed to fit specific application needs. This adaptability minimizes excess material use and significantly lowers production costs. As the electronics market continues to grow, businesses are increasingly recognizing the benefits of adopting flexible PCBs to enhance both their cost efficiency and product innovation, ultimately driving market expansion.

The market for flexible printed circuit boards (PCBs) is witnessing exponential growth, which underscores their increasing significance across various industries. The demand for lightweight, compact, and high-performance electronic components has propelled the adoption of flexible PCBs in sectors such as consumer electronics, automotive, medical devices, and telecommunications. Recent statistics indicate that the global flexible PCB market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years, highlighting their pivotal role in modern electronics design.

As industries strive for innovation, the versatility offered by flexible PCBs allows for advanced design capabilities, essential in developing next-generation devices. Companies are embracing these technologies to enhance the functionality and reliability of their products, especially as the trend towards miniaturization continues. The integration of flexible PCBs in wearable technology, for instance, showcases their adaptability and potential to meet evolving consumer needs. This growing trend points towards a future where flexible PCBs will not only dominate the electronics landscape but also drive advancements in related fields.

The future prospects for flexible PCBs are promising, driven by significant technological advancements and growing market adoption. The rising demand for miniaturization in electronics has led designers to seek alternatives to traditional rigid PCBs. Flexible PCBs offer greater design flexibility, allowing for compact and lightweight products essential in consumer electronics, wearables, and medical devices. As industries increasingly prioritize lightweight and space-efficient designs, the shift toward flexible PCBs becomes more pronounced.

Market insights indicate a robust growth trajectory for related technology sectors, such as wave soldering flux. The global market for wave soldering liquid flux, valued at $150 million in 2022, is projected to reach $250 million by 2030, reflecting a compound annual growth rate of 7.5% from 2024 to 2030. This growth underscores a broader trend in electronic manufacturing, where innovative materials and processes like flexible PCBs are gaining traction. The increasing emphasis on sustainability and energy efficiency further propels the adoption of flexible PCBs, positioning them as a crucial component in the future of electronics design.