In the rapidly evolving world of technology, the demand for PCB board assembly services is surging. Experts predict that 2026 will bring significant advancements in this field. Notably, John Smith, a leading expert in PCB manufacturing, emphasized, “The right assembly techniques can dramatically improve product performance.” This statement resonates as companies now prioritize efficiency and innovation.

The future of PCB board assembly hinges on selecting the best techniques. Companies must consider factors like speed, precision, and cost-effectiveness. Many businesses still rely on outdated methods. Yet, these approaches may not meet the increasing complexity of electronic devices. The integration of advanced technology is crucial.

Deciding on the best PCB board assembly service requires careful thought. Not every choice will yield optimal results. A common pitfall is overlooking supplier capabilities. As the industry grows, so does the need for reliable partnerships. Being mindful of these elements is essential for success in the PCB board assembly landscape.

In 2026, the landscape of PCB board assembly services will continue to evolve. Many manufacturers are embracing advanced techniques. Automation, for instance, improves efficiency and reduces human error. However, relying too heavily on machines can sometimes lead to oversights. It’s crucial to balance automation with skilled labor.

Soldering processes will also see advancements. The shift towards lead-free solder is gaining momentum. This change not only meets environmental standards but can complicate assembly techniques. Operators must adapt to new materials and methods. Training is essential, yet not all teams have the resources to stay updated.

Collaborative efforts among engineers, designers, and assemblers can enhance quality. Communication is key here. Clear lines prevent misunderstandings that could lead to defects. However, some companies struggle with these collaborations. They focus on speed rather than precision. Each misstep can cost time and resources. It’s a lesson that demands reflection.

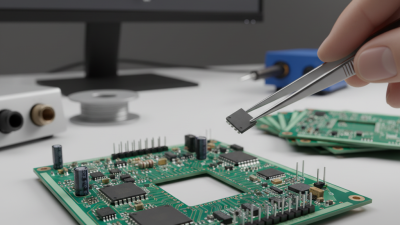

Efficient PCB assembly processes are essential for high-quality production. One crucial technique is automation. It helps speed up assembly and reduces human error. However, relying too much on machines can lead to problems. Operators should regularly monitor machines for calibration issues. Regular checks ensure quality is maintained throughout the process.

Another key technique is the use of selective soldering. This method allows precise solder application. It reduces the risk of bridging and improves reliability. Yet, it requires careful planning and can sometimes lead to missed connections if not managed properly. Understanding the layout and component placement is crucial. Communication among team members can bridge these gaps.

Finally, integrating design for manufacturability (DFM) principles is vital. It encourages engineers to consider assembly aspects early in the design phase. DFM helps in identifying potential pitfalls before production begins. Still, not all teams embrace this approach. Some might overlook communication, leading to last-minute changes. Emphasizing DFM can lead to smoother, more efficient production cycles.

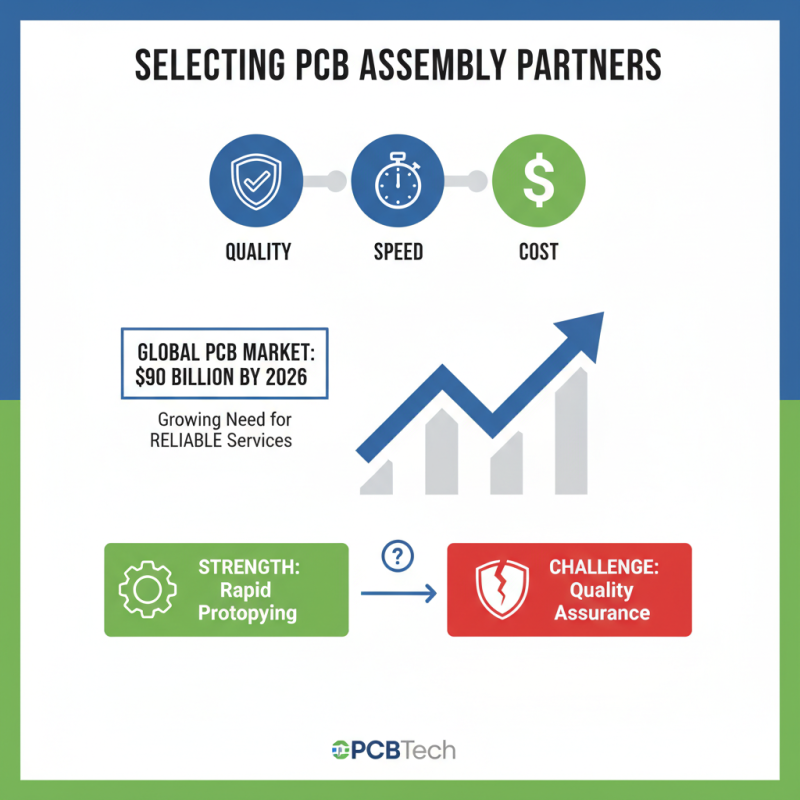

When evaluating PCB assembly service providers, it’s essential to consider key factors such as quality, speed, and cost. According to industry reports, the global PCB market is projected to reach $90 billion by 2026, reflecting a growing need for reliable assembly services. Many companies face challenges in selecting the right partner. Some providers may excel in rapid prototyping but fall short on quality assurance.

One important aspect is the provider's certification. Look for those with ISO 9001 or IPC standards. These certifications indicate a commitment to quality. A recent survey showed that 75% of companies prioritize quality over price when choosing PCB assembly services. Tip: Always request sample products before making a commitment. This ensures the provider meets your expectations.

Another point to reflect on is communication. It's crucial for a smooth process. If the provider lacks clear channels, delays can occur. A study found that 60% of assembly projects encounter delays due to poor communication. Tip: Establish regular check-ins to discuss project status. This keeps everyone aligned and aware of potential issues. Choose wisely to ensure successful collaboration in your PCB assembly journey.

Sustainability in PCB assembly is gaining traction. Industry reports indicate that electronic waste (e-waste) continues to be a serious concern. In 2022, around 57.4 million metric tons of e-waste were generated globally, with only 17.4% recycled properly. This alarming statistic highlights the urgent need for greener practices in PCB assembly.

One approach is the adoption of eco-friendly materials. Biodegradable substrates and lead-free solder are essential in reducing environmental impact. However, many manufacturers still lag behind in implementing these changes. Transitioning from traditional materials to sustainable options can be challenging and costly. A report from the International Journal of Electronics states that switching to greener materials may lead to a 20% increase in production costs initially. This hesitation to invest in sustainability reflects a gap between environmental responsibility and financial feasibility.

Additionally, life cycle assessments (LCAs) have become crucial for evaluating the environmental impact of PCB assemblies. These assessments help identify areas of improvement. Despite their importance, not all companies utilize LCAs effectively. Many only consider short-term costs. Balancing sustainability with profitability remains a complex challenge in the industry. Without a concerted effort towards sustainable practices, the PCB assembly sector risks contributing further to the growing e-waste crisis.

The future of PCB assembly technology is evolving rapidly. New techniques and services are reshaping the industry. Automation and artificial intelligence are leading the way. These advancements promise faster production and higher accuracy. However, companies must remain cautious. Relying too much on automation can lead to oversights. Human expertise is still needed for quality control.

One emerging trend is the adoption of environmentally friendly materials. Manufacturers are focusing on sustainable practices. This shift not only meets regulations but also appeals to eco-conscious consumers. Embracing green technologies can set companies apart. However, the transition to new materials presents challenges. It requires careful planning and adaptation.

Tips: Invest in training for your team. Encouraging skill development can improve efficiency. Keep up with industry trends. This will help you stay competitive. Networking with other professionals may provide insights into best practices. Engaging with the community can foster innovative ideas.

This bar chart illustrates the projected adoption rates of various trends in PCB board assembly services by 2026. Automation is expected to lead the charge, followed closely by AI integration and miniaturization practices, highlighting the industry's shift towards efficiency and sustainability.