When designing electronic circuits, the selection of PCB parts plays a crucial role in overall performance. High-quality components can enhance signal integrity and reduce power loss. However, not all PCB parts are created equal. Some manufacturers may prioritize cost over reliability, leading to subpar results.

Choosing the right PCB parts requires careful consideration. Factors such as thermal management, compatibility, and durability must be assessed. A well-designed PCB should not only meet the electrical requirements but also withstand external stresses. There is always a debate on which parts provide the best value.

Mistakes can occur during the selection process. It’s common to overlook minor details that, in hindsight, are significant. Some designers may find themselves stuck with components that don’t meet expectations. Understanding the importance of the right PCB parts is essential for achieving optimal circuit performance. Continuous learning and adaptation can lead to improvements in future designs.

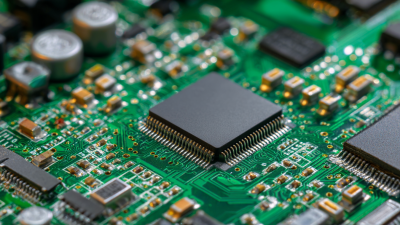

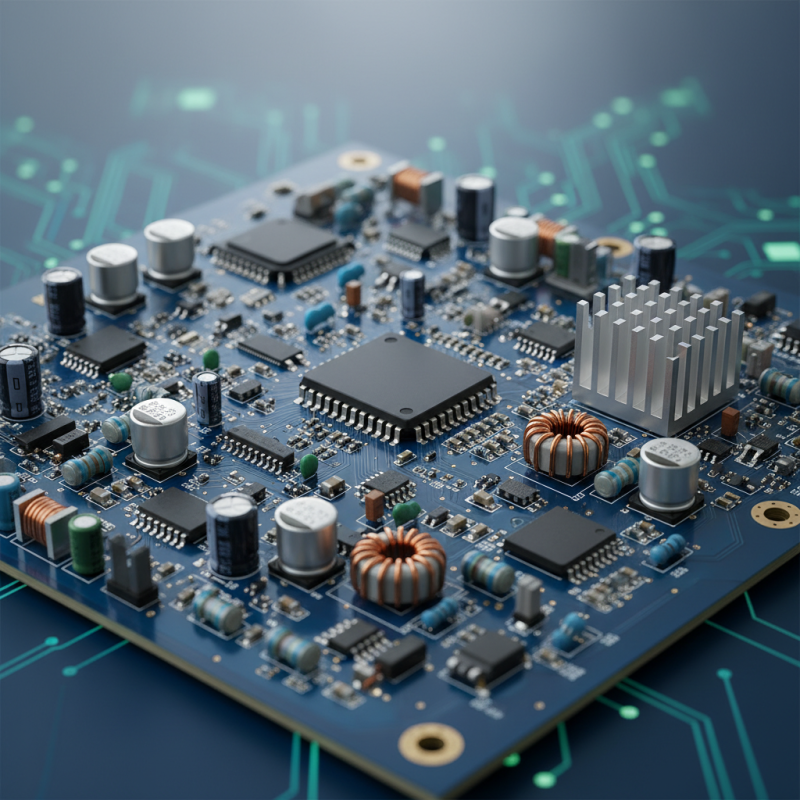

When designing a PCB, choosing the right components is crucial for optimal performance. Resistors, capacitors, and inductors are fundamental. Resistors control current flow, preventing damage to sensitive parts. Capacitors store and release energy, smoothing out voltage fluctuations. Inductors help in filtering signals, which reduces noise. Each component serves its unique purpose, ensuring that circuits operate as expected.

Connectors are also essential. They allow different PCB sections to communicate. Poorly designed connectors can lead to weak signals or failures. Additionally, integrated circuits (ICs) play a significant role. They combine multiple functions into one component, saving space on the board. However, IC selection requires careful consideration of their specifications and compatibility.

Lastly, power management components should not be overlooked. Voltage regulators stabilize power supply for sensitive circuits, ensuring consistency. Thermal management is another aspect; heat sinks dissipate excess heat. Skimping on these components can lead to performance issues. It is essential to reflect on your choices. Every component's role impacts overall circuit functionality. Without the right parts, even the best designs can falter.

When selecting PCB parts, performance is paramount. High-performance PCB parts must possess specific characteristics to ensure optimal functionality. One critical attribute is low signal loss. According to a report from IPC, minimizing signal degradation can improve circuit efficiency by up to 30%. Fine-tuning the material composition, such as using high-frequency laminates, is essential for reducing dielectric losses.

Thermal management plays a crucial role as well. PCBs can generate considerable heat, which affects performance. Research indicates that using parts with superior thermal conductivity can increase reliability and lifespan. For instance, materials with thermal conductivity above 1 W/mK are often recommended. This may seem straightforward, but not all parts meet these criteria. Inadequate thermal management can lead to system failures, resulting in increased costs and delays.

Environmental factors also impact PCB performance. High-quality components should resist moisture and chemicals. According to a study by PCB Design, roughly 15% of circuit failures stem from environmental influences. Using robust coatings and finishes is advisable. However, this can sometimes increase production costs. Balancing cost and quality remains a challenge. Poor decision-making here can compromise the entire project.

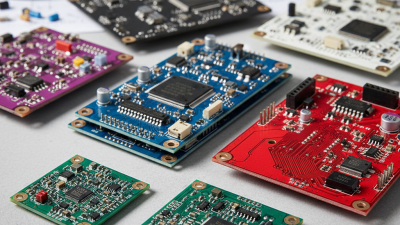

When selecting materials for PCB construction, performance is key. The right materials can significantly enhance circuit efficiency. For instance, copper is the main choice for traces due to its excellent conductivity. Yet, improper thickness can lead to overheating. Choosing the right thickness is essential.

Dielectric materials also matter. FR-4 is widely used, but it's not always the best option for high-frequency signals. In some cases, polyimide films can provide better performance. Temperature stability is crucial as well. Poor choice in this area can lead to circuit failure.

Surface finish is another factor. ENIG is popular for solderability, but it has drawbacks. Some surfaces can be prone to corrosion. Reflection and absorption can also impact circuit efficiency. Engineers must carefully consider details when selecting finishes. Each decision can influence the circuit's overall success. Balancing cost and performance remains a challenge.

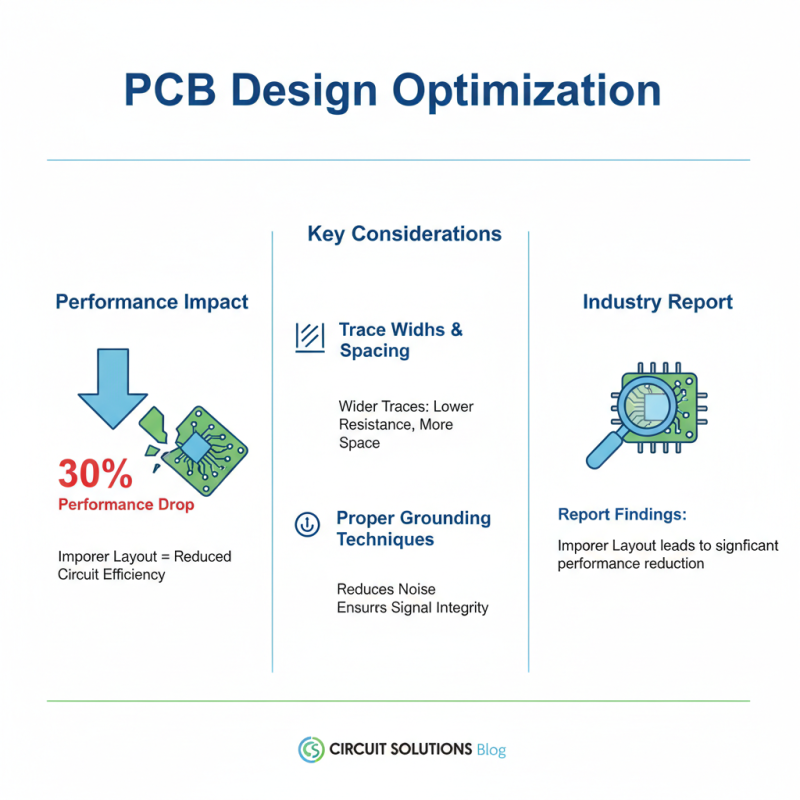

In PCB design, attention to layout and design can significantly enhance circuit performance. A recent industry report indicates that improper layout can lead to a staggering 30% performance drop. Key considerations include trace widths and spacing. Wider traces reduce resistance but take up more space, complicating designs. Proper grounding techniques also matter. Poor grounding can induce noise, impacting signal integrity.

**Tip:** Always incorporate vias effectively. Misplaced vias can add inductance and degrade performance. Aim for their placement based on signal paths.

Another consideration is component placement. This can impact both electrical performance and thermal management. Components that generate heat should be spaced out to avoid thermal coupling. Balancing aesthetics and functionality can lead to compromises.

**Tip:** Use simulation tools to analyze heat distribution. This can reveal potential overheating before production.

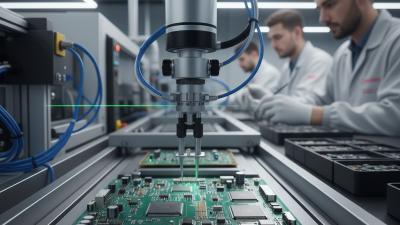

Furthermore, design for manufacturability is essential. Complex designs may face issues during assembly. Simplifying the layout can reduce production costs and defects in PCB soldering. Design rules should be applied judiciously. It’s easy to overlook minor details, which can result in significant failures.

Testing and optimizing PCB performance are essential for achieving optimal circuit functionality. A recent industry report notes that poor PCB design can lead to a 30% increase in failure rates. This statistic emphasizes the significance of thorough testing.

First, electrical tests such as impedance and continuity measurements help identify faults in the circuit layout. These tests reveal hidden issues that may affect performance.

Thermal testing is another vital aspect. According to data, 40% of PCB failures occur due to overheating. Ensuring that components are rated for their operational environment is crucial. Employing thermal imaging can detect hot spots on a PCB. These hot spots may go unnoticed during standard visual inspections. Heat dissipation techniques need to be evaluated regularly as well.

Lastly, signal integrity testing plays a critical role in optimizing performance. Signal degradation can impact communication in high-frequency applications. An analysis showed that 25% of signal integrity issues were traced back to improper grounding. This highlights the need for regular reviews of grounding methods and layouts.

Clear, concise documentation of each testing phase aids in continuous improvement. Each test provides insights into potential weaknesses that need attention.