In the realm of electronics, selecting the best PCB parts is crucial for project success. A recent industry report from Electronics Weekly highlighted that nearly 30% of engineering failures stem from inadequate material choices in PCB design. This statistic underscores the importance of quality components in achieving reliable performance.

Expert Joe McCarthy, a leading PCB parts consultant, once said, "The right components not only enhance functionality but also impact longevity." His insight reflects a common challenge faced by many engineers—finding the right balance between cost and quality. With an overwhelming number of options available, careful consideration is needed.

As technology progresses, the availability of new and innovative PCB parts continues to expand. Yet, this evolution can also overwhelm creators and lead to hasty decisions. Engineers often overlook crucial specifications, resulting in designs that may not withstand the intended conditions. Awareness of current trends and performance metrics is essential, as it ensures that projects not only meet immediate needs but also future demands.

When designing PCBs, selecting the right components is crucial. Essential elements like resistors, capacitors, and microcontrollers shape your project’s performance. According to industry reports, the global PCB market is expected to reach $80 billion by 2026. This growth emphasizes the need for quality components to ensure reliability.

Tips: Always verify component specifications. Many parts may seem similar but can have subtle differences in tolerance and size. For instance, choosing a capacitor with the wrong voltage rating can lead to failure. Also, be attentive to the layout. A poorly designed PCB can introduce noise, affecting the entire circuit.

More than just technical specifications, consider practical availability. Not all parts may be in stock. Components can face shortages or discontinuities that affect project timelines. Conduct regular reviews of your supply chain and be flexible in part selection. This adaptability can be crucial for the success of your electronics projects.

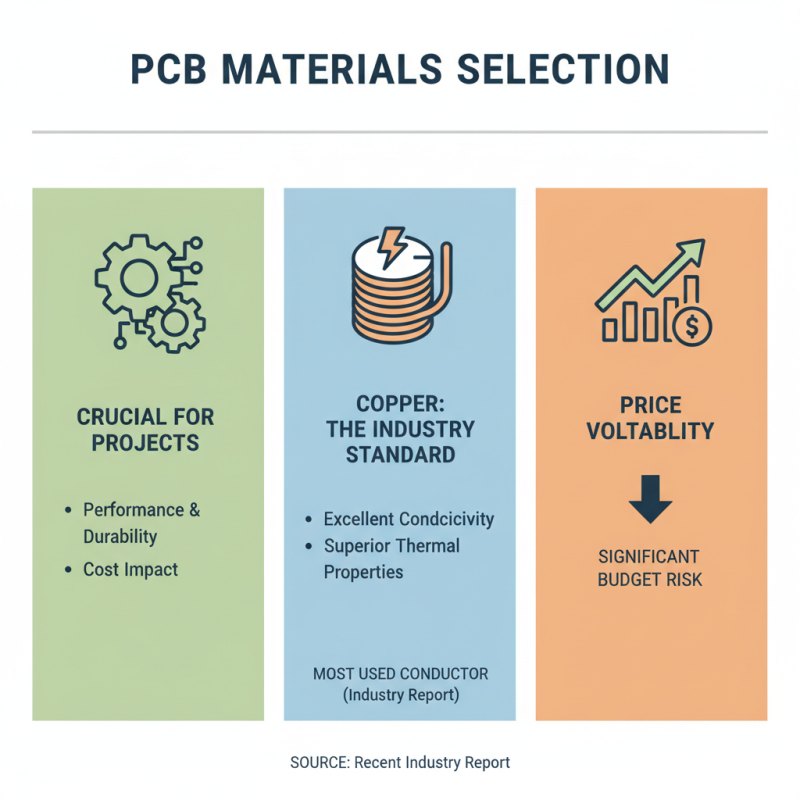

When undertaking PCB projects, selecting the right materials is crucial. The choice of materials affects performance, durability, and cost. According to a recent industry report, copper remains the most used conductor material due to its excellent conductivity and thermal properties. Yet, its price volatility can impact project budgets significantly.

Consider the substrate material as well. FR-4 is a common choice, offering good balance between cost and performance. However, this standard material can fail under extreme conditions. For projects requiring higher thermal resistance, materials like polyimide may be necessary. These can elevate costs, but they enhance reliability in harsh environments.

Component selection also plays a role. Using high-quality connectors can reduce failure rates. Studies indicate that up to 30% of PCB failures stem from poor connections. Despite this knowledge, some designers opt for cheaper alternatives. Reflecting on the long-term reliability and overall project costs is essential. Balancing quality and budget is no easy task.

When selecting the best PCB parts for electronics projects in 2026, it is essential to consider reliable manufacturers and suppliers. According to market analysis firm IDTechEx, the global PCB market is projected to reach $83 billion by 2026. This growth reflects an increasing demand for high-quality, efficient PCB solutions in various applications, from automotive to consumer electronics.

Quality can vary widely among suppliers. Some companies focus on advanced technologies, while others may overlook critical quality control steps. Reports indicate that 25% of PCBs do not meet the desired specifications on the first production run. This emphasizes the importance of rigorous testing and validation procedures.

Many manufacturers not only provide PCBs but also offer design assistance. This can be beneficial for small projects. Nonetheless, a few firms lack robust customer support. Feedback from engineers often highlights communication gaps and delayed response times. It’s crucial to engage with suppliers and assess their support networks before making decisions. In an increasingly competitive landscape, understanding both strengths and shortcomings can lead to more informed choices.

Innovative technologies are reshaping printed circuit boards (PCBs) for electronics projects. New materials enhance conductivity and flexibility. Designers are experimenting with organic substrates, which reduce environmental impact. These materials often lead to lighter designs and improved performance.

Advanced techniques like 3D printing are changing how PCBs are made. Rapid prototyping allows for quick iterations. This speeds up development cycles significantly. However, creating reliable connections in these prototypes can be challenging. Some designs may fail due to misaligned layers or poor adhesion.

Flexible PCBs are gaining traction in wearable tech. They conform to various shapes, making them ideal for tight spaces. Yet, durability can be a concern. They may wear out faster than traditional boards in some applications. As innovations continue, the industry must balance performance and usability. Each advancement presents new challenges and areas for reflection.

Sourcing PCB parts efficiently requires a clear strategy. Start by identifying your project needs. Define the specifications and quantities of each component. This will streamline your search. Use online databases and marketplaces to compare options. Look for detailed datasheets to ensure compatibility.

Consider the lead times and shipping costs. Sometimes, cheaper parts come with longer waits. This can delay your project timeline. Aim for a balance between cost and speed. Engaging with local suppliers might offer quicker alternatives but at different price points.

It’s crucial to check reviews and community feedback on vendors. Not all suppliers deliver quality products. This step can save you from unexpected issues during assembly. Reflect on past sourcing experiences. Learning from mistakes can refine your current approach.