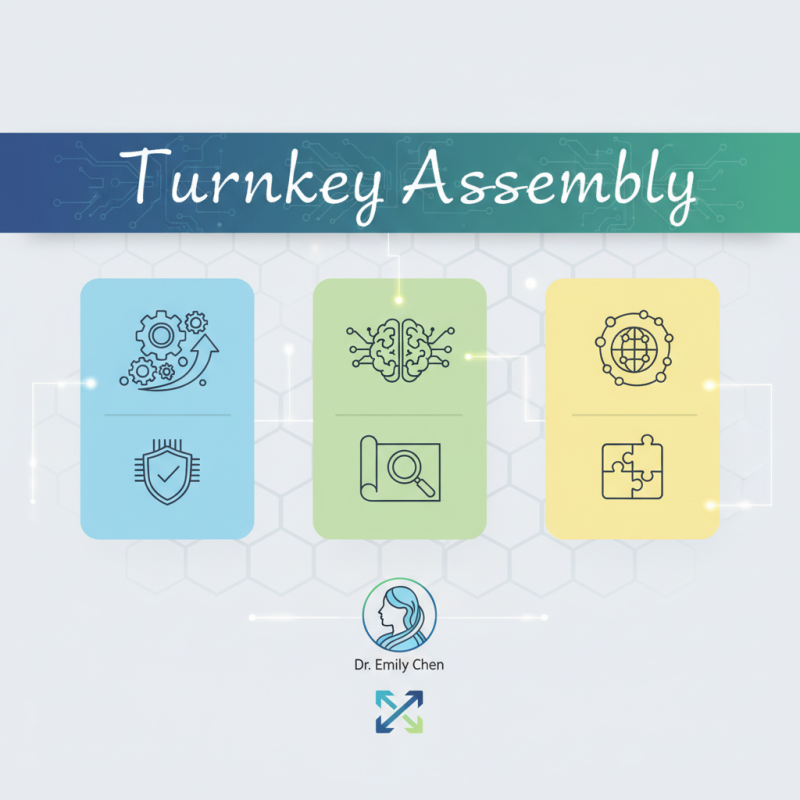

In the rapidly evolving landscape of electronics manufacturing, selecting the right turnkey PCB assembly service can significantly impact the success of your project. With the demands for higher efficiency and reduced time-to-market, the role of dependable turnkey PCB assembly providers becomes paramount. Renowned industry expert Dr. Emily Chen, a leading voice in PCB technology, emphasizes, “Choosing a turnkey PCB assembly service is not just about cost; it's about finding a partner that aligns with your goals and can scale with your project’s needs.”

As businesses strive for innovation, the need for comprehensive solutions that cover everything from design to production becomes essential. By understanding the defining factors of a great turnkey PCB assembly service, such as quality assurance, technical expertise, and supply chain management, companies can ensure they partner with the right service provider. This guide will explore key considerations and best practices to streamline your decision-making process and set your project up for success in a competitive market.

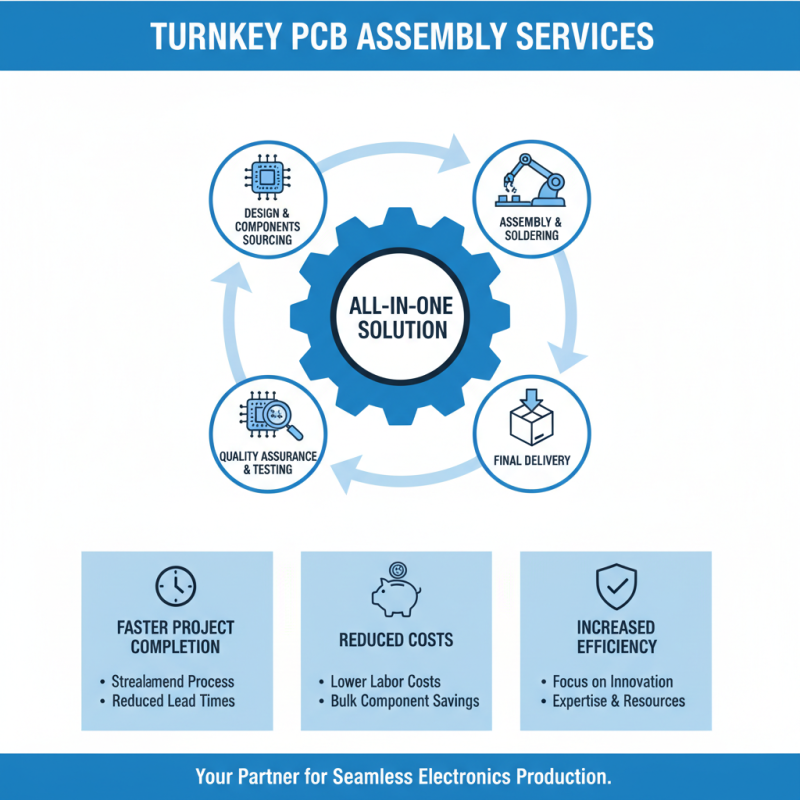

Turnkey PCB assembly services are an efficient solution for engineers and businesses looking to streamline their production process. These services encompass the entire assembly process—from the initial design to the final testing—allowing clients to focus on other crucial aspects of their projects. By choosing a turnkey provider, companies benefit from a comprehensive approach that often leads to faster project completion times and reduced labor costs. This all-in-one service model is particularly advantageous for those who may lack the resources or expertise to source components, assemble the PCB, and conduct quality assurance independently.

One of the key advantages of turnkey PCB assembly is the ease of coordination. With a single point of contact handling all aspects of the assembly, clients can expect improved communication and a more cohesive workflow. This can significantly lower the risk of misunderstandings and errors that might arise when working with multiple vendors. Additionally, many turnkey services offer robust quality control measures, ensuring that each assembled board meets the required standards before delivery. This not only enhances reliability but also contributes to a more streamlined supply chain, ultimately benefiting the overall production timeline and reducing overhead costs.

When selecting a turnkey PCB assembly provider, several critical factors must be considered to ensure the success of your project. First, evaluate the manufacturer’s capabilities and certifications. According to IPC (Institute of Printed Circuits), a reputable PCB assembler should hold relevant certifications such as ISO 9001 and IPC-A-610, which indicate compliance with industry standards. This not only assures quality but also demonstrates their commitment to continuous improvement processes. Additionally, assess the technology employed by the service provider; companies using advanced automation and inspection methods typically produce higher-quality assemblies, reducing the risk of defects that could derail your project timeline.

Another important factor is the provider's supply chain management. A comprehensive report by the Research & Markets indicates that disruptions in supply chains can lead to increased costs and delays in PCB assembly services. Therefore, it is crucial to partner with a provider that has established relationships with reliable component suppliers and demonstrates a robust inventory management system. This minimizes lead times and ensures that you have access to the necessary components without unexpected shortages. Lastly, consider the provider’s customer service and communication protocols; an effective partnership requires transparency and responsiveness throughout the assembly process.

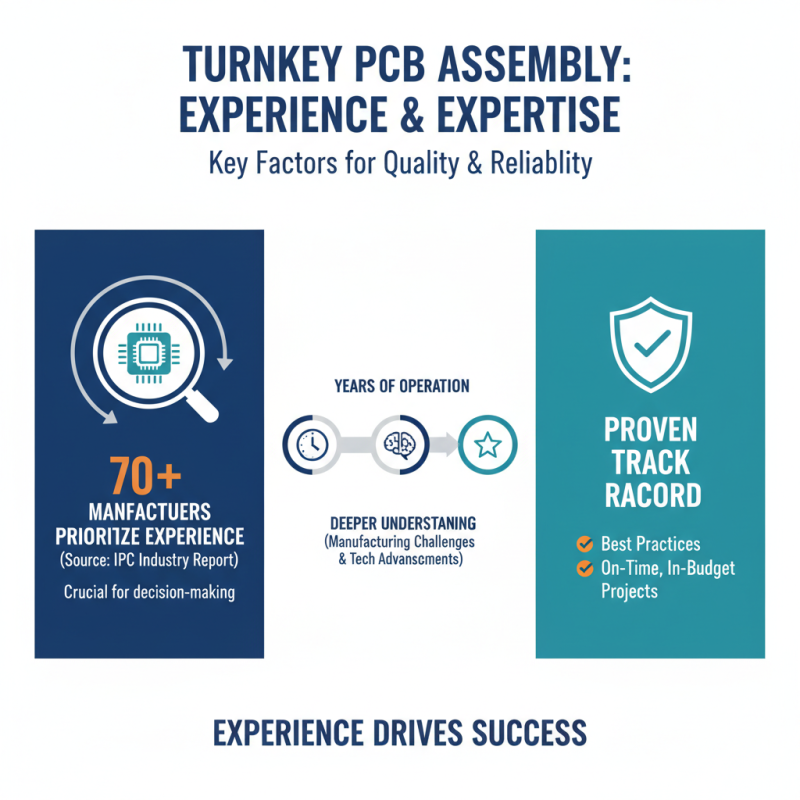

When selecting a turnkey PCB assembly service, evaluating the experience and expertise of the company is crucial. According to a recent industry report by IPC, over 70% of electronics manufacturers prioritize experience as a key factor in their decision-making process. Companies with several years of operation typically possess a deeper understanding of manufacturing challenges and technological advancements, which can significantly impact the quality and reliability of the assembled PCB. Those with a proven track record in producing high-quality boards are more likely to employ best practices, thus ensuring that projects are completed on time and within budget.

Additionally, it is important to assess the skill levels of the staff involved in the PCB assembly process. A study by the Electronics Industry Association indicates that companies with certified engineers and technicians demonstrate a 30% increase in production efficiency and a reduction in defect rates. Moreover, firms that invest in ongoing training and development for their workforce are better equipped to handle complex designs and evolving technologies. By scrutinizing the qualifications and expertise of the assembly team, businesses can ensure a higher standard of service and technical support, leading to a more successful project outcome.

When selecting a turnkey PCB assembly service, understanding the various pricing models and services offered by different providers is crucial for ensuring the optimal fit for your project. Many companies in the industry employ different pricing strategies, such as fixed pricing, variable pricing, or a combination of both. According to the IPC's 2021 PCB Market Report, the average cost per square inch for PCB assemblies can vary significantly, from as low as $0.50 to over $5.00 depending on the complexity of the design and materials used. This variability emphasizes the importance of exploring multiple quotes and understanding what factors are influencing these costs.

In addition to pricing, the range of services provided can greatly impact the overall value and efficiency of your project. Some turnkey providers offer extensive supply chain management, while others may specialize in quick-turn prototypes. The SMTA's 2022 Service Capability Benchmarking Report highlights that over 65% of manufacturers seeking PCB assembly services prioritize vendors that provide additional services, such as design support and post-manufacturing testing. Thus, evaluating providers based on their ability to deliver comprehensive solutions that align with your project's specific needs can yield significant long-term benefits.

| Provider Type | Pricing Model | Lead Time | Minimum Order Quantity | Services Offered |

|---|---|---|---|---|

| Full-Service PCB Assembly | Cost-Plus Pricing | 4-6 Weeks | 10 Units | Design Review, Sourcing, Assembly |

| Prototype PCB Assembly | Fixed Pricing | 2-3 Weeks | 5 Units | Rapid Prototyping, Testing Services |

| Low-Cost PCB Assembly | Volume-Based Pricing | 6-8 Weeks | 100 Units | Basic Assembly, Quality Control |

| Specialized PCB Assembly | Hourly Rate | 4 Weeks | 1 Unit | Complex Assembly, Custom Solutions |

When selecting a turnkey PCB assembly service, one of the most crucial factors to consider is the quality assurance practices that the service provider implements. Quality assurance should be ingrained in every step of the assembly process, from initial design reviews to final product inspection. A reliable service will employ rigorous testing protocols, including automated optical inspection, electrical testing, and functional testing, to ensure that every PCB meets the specified requirements. By assessing these practices, you can gain insight into the reliability and durability of the products you will receive.

In addition to quality assurance, robust customer support is essential for a successful partnership with your PCB assembly provider. This support can encompass various aspects, such as technical guidance, timely communication during the assembly process, and after-sales service. Look for companies that offer dedicated support teams and transparent channels for feedback and inquiries. The ability to collaborate closely with experienced professionals throughout the project's lifecycle can significantly enhance the overall outcome, ensuring that any issues are promptly addressed and resolved. Prioritizing both quality assurance and customer support will ultimately lead to a smoother assembly process and superior end products.