In the rapidly evolving landscape of electronics, the demand for flexible printed circuit boards (flexible PCBs) has surged due to their remarkable adaptability and lightweight characteristics. According to a recent market analysis by MarketsandMarkets, the flexible PCB market is projected to grow from USD 18.5 billion in 2022 to USD 29.2 billion by 2027, highlighting the increased reliance on this technology across various sectors including consumer electronics, automotive, and medical devices. This significant growth emphasizes the necessity for engineers and product developers to select the best flexible PCB tailored to their project needs and budget constraints.

When navigating the complexities of flexible PCB selection, various factors come into play such as material types, thickness, layer count, and manufacturing techniques. The flexibility of these circuits allows for innovative designs that fit increasingly compact and dynamic applications, thus making them a preferred choice for modern devices. However, balancing performance requirements with cost considerations is critical for project success. By understanding the specifications and capabilities inherent to flexible PCBs, stakeholders can make informed decisions that will optimize both functionality and budget, ensuring their projects not only meet but exceed the demands of today's technology-driven market.

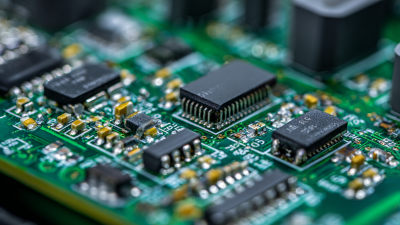

Flexible printed circuit boards (PCBs) represent a significant advancement in electronic design, enabling compact and lightweight products that can fit into various shapes and spaces. Understanding the basics of flexible PCBs is crucial for anyone looking to incorporate them into their projects. Unlike traditional rigid PCBs, flexible PCBs can bend and twist, making them ideal for applications in consumer electronics, automotive, aerospace, and medical devices. Their ability to conform to specific spatial constraints allows for more innovative designs and improved functionality.

Applications of flexible PCBs are diverse and growing rapidly. In the consumer electronics sector, they enable the creation of thinner devices like smartphones and wearables, where space is at a premium. In the automotive industry, flexible PCBs are used in advanced driver-assistance systems (ADAS) and infotainment systems, contributing to enhanced performance and reliability. Furthermore, in medical devices, flexible PCBs facilitate miniaturization and flexibility, essential for wearable health monitors and intra-body devices. Understanding these applications will help you make informed decisions when selecting the best flexible PCB to meet your project needs and budget.

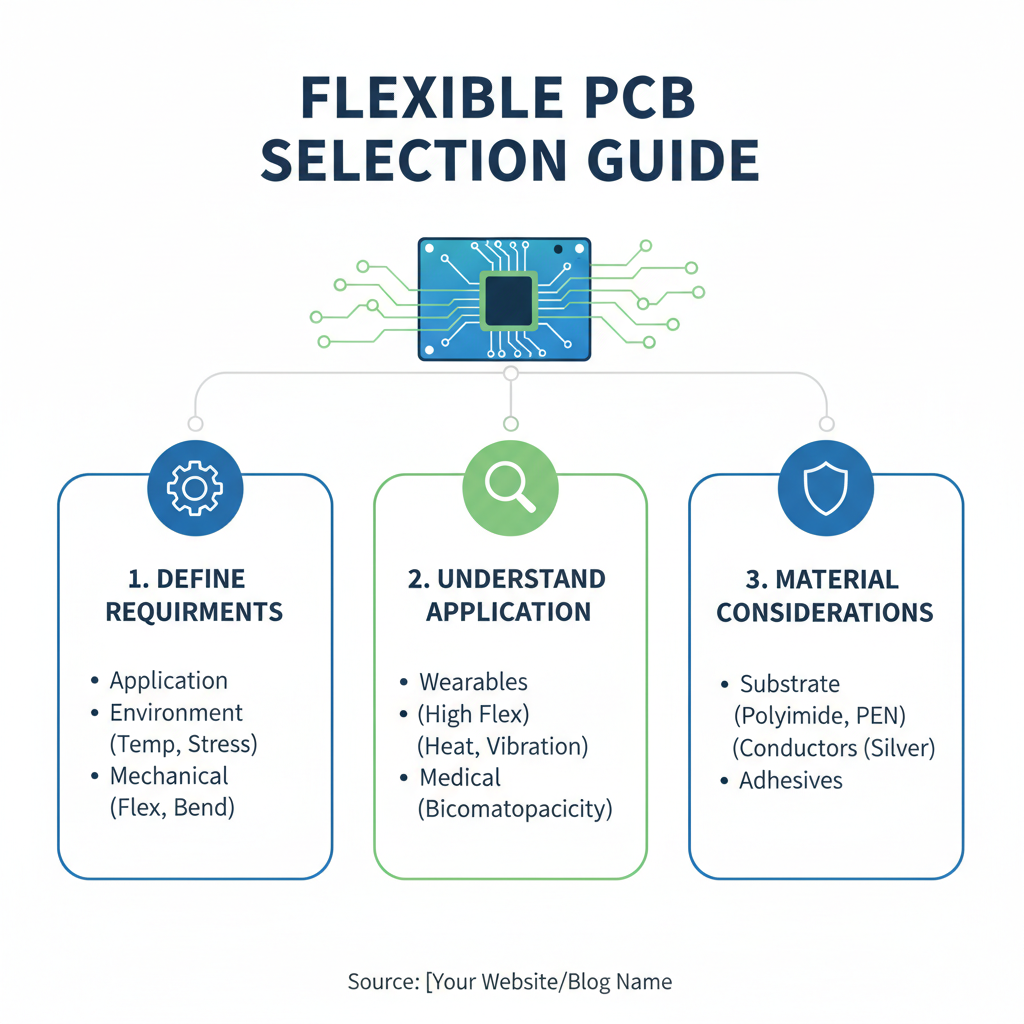

When selecting the best flexible printed circuit board (PCB) for your project, it's crucial to begin by clearly identifying your project requirements and specifications. Understanding the intended application of the PCB is fundamental; consider factors such as the operating environment, expected temperature ranges, and the mechanical stress the board will endure. For instance, applications in wearable technology may necessitate a PCB that can withstand bending and flexing without compromising performance.

Next, take into account the electrical specifications, including the type of components you plan to use and the required signal integrity. Assess the impedance control, layer stack-up, and any specific routing needs to ensure that the flexible PCB supports your circuit design effectively. It's also important to evaluate the available space for the PCB, as flexibility can offer innovative solutions in compact or irregular layouts. By meticulously outlining these project requirements, you can make a more informed decision that aligns your needs with your budgetary constraints, leading to a successful project outcome.

When considering the budget and cost implications for flexible printed circuits boards (PCBs) in your project, it’s crucial to evaluate various factors that influence overall expenses. The flexibility of the PCB design often translates to higher production costs, which can be justified by the enhanced performance and reliability these boards offer, especially in applications like automotive electronics. With the global automotive PCB market projected to reach $15.10 billion by 2032, understanding the balance between cost and reliability becomes essential.

Additionally, advancements in production technologies can significantly affect pricing structures. For instance, new processes aimed at enhancing efficiency in flexible circuit production mean that while initial costs may be higher, the long-term savings and performance gains could offer a superior return on investment. As manufacturers innovate to produce more affordable and effective flexible PCBs, it’s important to factor in not just the sticker price but also the value gained through reduced material waste and improved product longevity.

When selecting the appropriate flexible PCB materials for your project, it's vital to understand the different types available. Common materials include polyimide (PI), polyester (PET), and thin-film technologies. Polyimide is valued for its excellent thermal stability and can withstand high temperatures, making it suitable for demanding applications such as aerospace and medical devices. On the other hand, polyester is more cost-effective and offers good flexibility, making it a popular choice for consumer electronics where budget constraints may be a priority.

In addition to material selection, it's essential to consider the various manufacturing technologies that influence the performance and capabilities of flexible PCBs. Techniques such as sequential lamination and additive print technologies can optimize circuit density and provide better design versatility. Sequential lamination allows for greater layer buildup while minimizing thickness, making it perfect for high-density interconnects. Additive printing, meanwhile, can reduce waste and enable the creation of complex geometries. Evaluating these factors will help you choose the best flexible PCB tailored to your specific project requirements and budget.

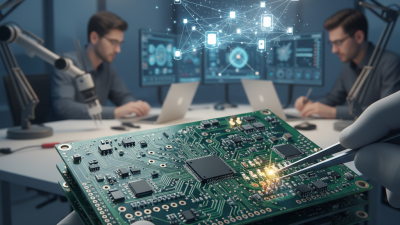

When selecting a manufacturer for high-quality flexible PCBs, it's essential to consider key factors that significantly impact the production and final product quality. According to industry reports, the flexible PCB market is projected to reach $24 billion by 2025, emphasizing the growing demand for reliable suppliers. A manufacturer with a proven track record in flexible PCB production should have the necessary certifications, such as ISO 9001 and IPC standards, indicating their commitment to quality and reliability.

**Tips:** Always request samples or prototypes before placing a large order. This allows you to assess the manufacturer's capabilities, quality control processes, and their response time to feedback. Additionally, review customer testimonials and case studies to gauge their experience with similar projects.

Another important aspect is the manufacturer's technological capabilities. Advanced manufacturing techniques, such as automated assembly and precision etching, can significantly enhance the reliability and performance of flexible PCBs. A report by MarketsandMarkets suggests that innovations in materials and processes will drive the flexible PCB industry forward, making it vital to partner with a manufacturer who invests in R&D and stays updated with industry trends.

**Tips:** Look for manufacturers who offer continuous support and consultation throughout the production process. This collaboration can lead to design optimizations and cost savings, ensuring that your project stays on track and within budget.