In the evolving landscape of electronics, selecting the right rigid flex PCB is crucial for project success. Industry expert Dr. Emily Chen emphasizes, "The choice of a rigid flex PCB can make or break your design." This statement resonates with many engineers facing complex design challenges.

Rigid flex PCBs offer unique advantages, combining the best of both rigid and flexible circuits. They enable compact designs and reduce assembly costs. However, with various options on the market, making the right choice can be overwhelming. For example, considering factors like material quality, layer count, and intended application can significantly impact performance.

Many engineers still struggle with this decision. They might choose a PCB without fully understanding its implications on design and functionality. Reflecting on past experiences can help avoid common pitfalls. Engineers should take the time to assess their specific needs before making a decision. Understanding these nuances will lead to better project outcomes in the long run.

Rigid flex PCBs combine flexibility and rigidity in a single structure. This unique characteristic makes them suitable for various applications. A rigid flex PCB consists of both flexible and rigid materials, allowing for complex designs. They are often used in devices where space is tight, like smartphones or medical equipment. Their lightweight nature helps improve performance while reducing the overall weight of the device.

In automotive and aerospace industries, rigid flex PCBs are gaining popularity. They withstand harsh conditions and vibrations better than traditional PCBs. However, choosing the right design can be challenging. Engineers need to balance flexibility, thermal management, and mechanical stress. Each project has specific requirements, which adds a layer of complexity. Prototyping may reveal unexpected issues. Understanding how to integrate these boards can be a learning curve. Emphasizing the right materials and designs will lead to success.

Choosing the right rigid flex PCB material is crucial for your project. Different applications demand different characteristics. For example, if you need durability, materials like polyimide or polyester are worth considering. These materials offer excellent flexibility while maintaining mechanical strength.

Another aspect to think about is thermal stability. This can affect performance and lifespan. Some materials may not withstand high temperatures well. If your device generates heat, look for options that can handle it. This might limit your choices, leading to some hard decisions.

Conductivity is another vital factor. High-frequency applications often require specific copper thicknesses. Yet, achieving the desired balance between flexibility and conductivity can be tricky. Sometimes, you may have to rethink your layout or components. It's essential to weigh these aspects carefully before proceeding with your design.

| Key Factor | Description | Recommended Material |

|---|---|---|

| Layer Count | Determine the number of layers needed for signal integrity and complexity. | FR-4, Polyimide |

| Flexibility | Assess the amount of bending required in the application. | Polyimide |

| Thermal Properties | Understand the temperature range the PCB will operate in. | High-TG FR-4, Polyimide |

| Electrical Performance | Consider the dielectric constant and loss for signal integrity. | Low-loss materials |

| Surface Finish | Select the appropriate surface finish for solderability and lifespan. | HASL, ENIG |

| Cost | Analyze budget constraints while ensuring material functionality. | Various cost-effective options |

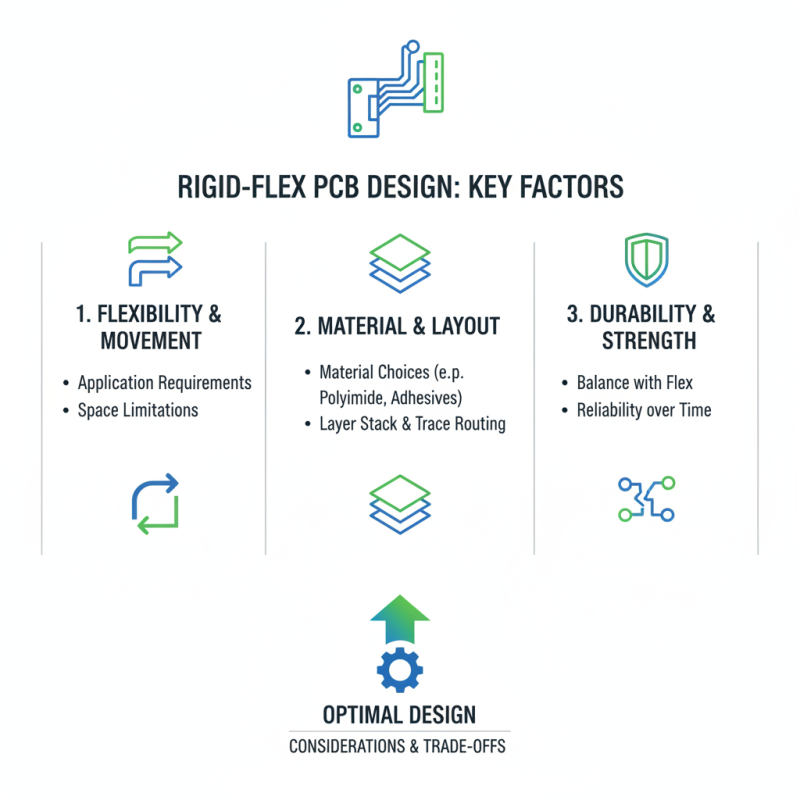

When designing a rigid flex PCB, flexibility is a key factor. Understanding the application requirements is critical. You need to consider the space limitations and the design’s intended movement. This often leads to trade-offs in material choices and layout designs. Flexibility can conflict with strength. Sometimes, engineers overlook the balance between durability and flexibility.

Material selection is crucial for achieving the right flexibility. Common choices include polyimide, which offers excellent flexibility. However, it might not always suit your project. You need to look at thermal properties, weight, and cost. Each decision impacts the final product. Prototyping can help identify potential issues early in the design phase. Iterating designs based on testing often reveals unforeseen challenges that need addressing.

Design techniques play a significant role in achieving desired flexibility. Adding controlled bends and avoiding sharp angles can help maintain functionality. However, designing for flexibility can be complex and may require multiple iterations. It's essential to remain flexible in your approach too. Some designs may not work as initially intended. It’s this trial-and-error process that leads to better solutions. Always remember, the journey is as important as the destination.

Choosing the right rigid flex PCB begins with understanding manufacturer capabilities. Evaluate their experience in various industries. Look for a track record in producing PCs matching your specifications. Not all manufacturers can manage complex designs. Some may excel in high-volume production while others are suited for niche applications.

Tips: Always ask for samples from potential manufacturers. This helps assess their work quality. Examine the layers and flexibility. A good sample reveals their attention to detail. If the sample doesn’t meet your expectations, rethink your choice.

Consider the technology used in fabrication. Advanced machinery can enhance quality and reliability. But, some manufacturers may not invest in the latest tools. This could lead to production delays or defects. Inspect their certifications too. Compliance with industry standards is crucial. Without it, you might face unexpected issues down the line.

Tips: Research their customer reviews and feedback. Good feedback is often a sign of reliability. Communicate openly about your needs. A responsive manufacturer is essential for a successful project. Make sure they can adapt if requirements change.

Choosing the right rigid flex PCB for your project requires careful cost analysis. Various factors affect your budget, including design complexity, material quality, and production volume. According to a 2023 industry report, an average rigid flex PCB can cost between $5 and $20 per square inch. This wide range depends significantly on specific project requirements.

When budgeting, consider hidden costs. Prototype iterations can quickly inflate expenses. Industry data suggests that around 30% of the total budget may go toward design changes and revisions. Inflexible timelines may lead to rushing, increasing costs further. Poor communication with suppliers can also result in unexpected charges. Tracking every detail is crucial.

Additionally, quality impacts long-term costs. Cheaper materials may reduce initial expenditure but could lead to failures. A 2022 study indicated that 25% of PCBs fail due to subpar materials. Long-term reliability is vital. Balancing upfront costs with quality will ensure a successful project. Always reflect on decisions made during the budgeting phase.