In the era of rapid technological advancements, the significance of circuit board assembly (CBA) in modern electronics cannot be underestimated. According to a recent report by the International Electronics Manufacturing Initiative (iNEMI), the global market for circuit board assembly is expected to reach approximately $72 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth is driven by increasing demands for sophisticated electronic devices in various sectors, such as automotive, healthcare, and consumer electronics.

Experts highlight the critical role of circuit board assembly in the development and functionality of electronic products. Dr. Emily Tran, a renowned expert in electronics manufacturing, states, "The precision and quality of circuit board assembly processes directly influence the performance and reliability of electronic devices." This underscores the importance of adopting advanced assembly techniques and technologies to meet the evolving requirements of the electronics industry.

As devices become smaller and more intricate, the complexity of circuit board assembly processes continues to rise. This evolution necessitates a deeper understanding of assembly methods and materials to ensure efficient production and exceptional performance. Ultimately, investment in high-quality circuit board assembly is essential for fostering innovation and sustaining growth in the competitive electronics landscape.

Circuit board assembly is a fundamental process in modern electronics, serving as the backbone for a vast array of devices that we depend on daily. This process involves the placement of electronic components onto a printed circuit board (PCB), which provides both mechanical support and electrical connections. The accuracy and efficiency of circuit board assembly directly influence a device's performance, reliability, and lifespan, making it crucial in the high-paced technology landscape where consumers expect rapid advancements and seamless functionality.

The importance of circuit board assembly extends beyond mere functionality; it encompasses quality control and innovation in design. As devices become increasingly compact and complex, the assembly process must adapt to accommodate advanced technologies, such as miniaturized components and multilayered PCBs. These innovations optimize space and enhance performance while reducing power consumption.

Moreover, precision in assembly contributes to the overall durability of electronic devices, which is essential for consumer satisfaction and brand reputation in a competitive market. Thus, the meticulous process of circuit board assembly is not just a technical necessity; it is a critical component in the evolution of modern electronics.

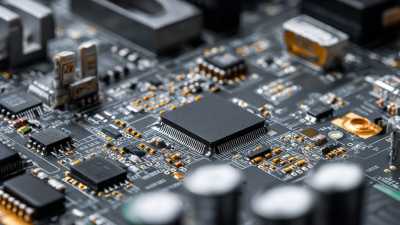

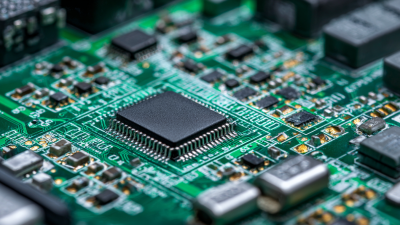

Circuit board assembly is a fundamental process in modern electronics, relying heavily on various components, each playing a crucial role in the functionality of the final product. A printed circuit board (PCB) is composed of resistors, capacitors, inductors, diodes, and integrated circuits, among other elements.

Resistors help in controlling the flow of electric current, ensuring that each component receives the appropriate voltage. Capacitors store and release energy, stabilizing power supply and filtering signals to enhance performance. Inductors, on the other hand, are used in conjunction with capacitors to filter frequencies, playing an important role in signal processing.

Moreover, diodes and integrated circuits (ICs) are essential for directing current flow and processing information. Diodes allow current to pass in one direction only, protecting sensitive components from potential damage caused by reverse voltage. Integrated circuits combine numerous electronic components into a single chip, thereby minimizing space and enhancing performance. These elements are meticulously assembled on the circuit board, often using automated processes, to ensure precision and reliability.

Understanding the function of these components is vital, as they are integral to creating efficient and effective electronic devices that power our everyday lives.

The process of circuit board assembly (CBA) is a crucial component of modern electronics, transforming intricate designs into functional devices. It begins with the fabrication of the printed circuit boards (PCBs), where the layout is etched onto a substrate material, typically fiberglass. This step ensures that the conductive pathways are in place for electrical connectivity. After the PCBs are prepared, the next phase involves placing the electronic components onto the board. This is done using methods like surface mount technology (SMT) or through-hole technology, depending on the design requirements.

Once the components are accurately positioned, they undergo soldering, which secures them in place. This can be accomplished through various techniques, such as wave soldering or reflow soldering, each suited for different scenarios and component types. After soldering, the assembly is tested for functionality and reliability through rigorous quality control checks, including visual inspections and automated testing methods. Finally, any necessary finishing touches such as surface coating and packaging are applied, preparing the assembled circuit boards for integration into electronic devices. This meticulous step-by-step process not only ensures the performance of electronics but also contributes to the overall efficiency and scalability of modern manufacturing.

| Step | Description | Importance |

|---|---|---|

| 1 | Designing the Printed Circuit Board (PCB) | Lays out the circuit paths and placement of components accurately. |

| 2 | Printing the Circuit Board | Creates the physical structure to support electrical components. |

| 3 | Component Placement | Ensures precise positioning of all electronic components for proper functionality. |

| 4 | Soldering Components | Connects components securely to the board, ensuring durability. |

| 5 | Testing the Assembly | Verifies functionality and identifies any defects in the assembly. |

| 6 | Final Inspection | Ensures that the finished product meets quality standards and specifications. |

The circuit board assembly (CBA) process is vital for ensuring that modern electronics function effectively and reliably. However, this process comes with several challenges that stakeholders in the industry must navigate. One of the primary challenges is maintaining quality and precision during assembly. As components become smaller and more intricate, the risk of errors increases, leading to potential malfunctions. Manufacturers must invest in advanced machinery and skilled technicians to mitigate this risk, utilizing automated systems that enhance precision and reduce the likelihood of human error.

Another significant challenge is managing the supply chain effectively. With the growing complexity of electronic devices, sourcing high-quality components from various suppliers can lead to delays and increased costs. Additionally, global events can disrupt supply lines, making it essential for manufacturers to develop flexible sourcing strategies. Implementing technologies such as real-time inventory tracking systems and fostering strong relationships with multiple suppliers can help address these issues, ensuring a more consistent flow of materials and enabling manufacturers to respond swiftly to market demands.

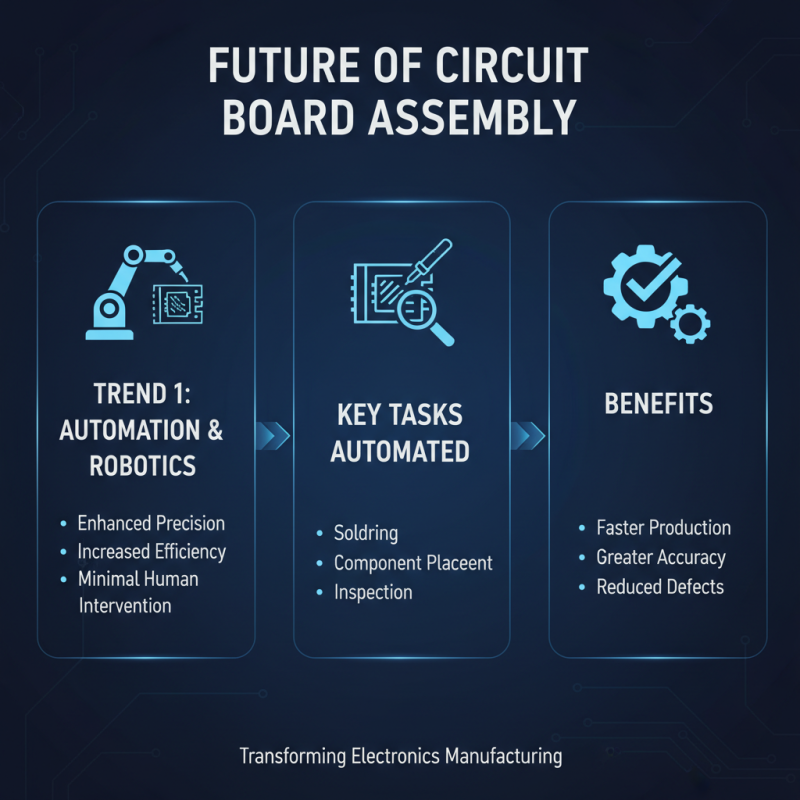

The future of circuit board assembly technology is set to transform the electronics landscape through several emerging trends. One notable trend is the increasing adoption of automation and robotics in the assembly process. These technologies enhance precision and efficiency, allowing manufacturers to produce circuit boards with minimal human intervention. Automated systems can perform tasks such as soldering, component placement, and inspection faster and more accurately than traditional methods, significantly reducing the risk of defects.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms is poised to revolutionize quality control and testing processes within circuit board assembly. By analyzing data from production runs, these advanced systems can identify patterns and predict potential failures, enabling proactive measures that enhance product reliability. Additionally, AI-driven systems can adapt to various production environments, optimizing processes in real-time to maintain high standards of quality.

Lastly, the continued miniaturization of components is leading to the development of more sophisticated assembly techniques. This trend necessitates innovations in both materials and technologies, such as improved soldering techniques and the use of flexible printed circuit boards. As electronic devices become smaller and more complex, the ability to efficiently assemble tightly packed components while maintaining performance and durability will become increasingly crucial for manufacturers seeking to meet consumer demands.