In the realm of electronics manufacturing, the process of circuit board fabrication plays a pivotal role in determining the success and efficiency of production. As the backbone of virtually all electronic devices, circuit boards serve as the crucial medium through which electrical components communicate and function cohesively. The demand for high-quality, precision-engineered circuit boards has surged alongside the rapid advancements in technology, emphasizing the importance of mastering the fabrication process.

Circuit board fabrication encompasses various critical steps, including design, etching, and assembly, which must be executed with precision to ensure the reliability and performance of the final product. A well-fabricated circuit board not only facilitates optimal connectivity and signal integrity but also contributes to the overall durability and longevity of electronic devices. Manufacturers must adopt innovative techniques and leverage cutting-edge technology to keep pace with evolving consumer expectations and industry standards.

Ultimately, understanding the intricate relationship between circuit board fabrication and electronics manufacturing success is essential for businesses aiming to thrive in a competitive landscape. By prioritizing quality and efficiency in fabrication processes, manufacturers can enhance product performance, reduce time-to-market, and bolster customer satisfaction, thereby securing a sustainable foothold in the world of electronics.

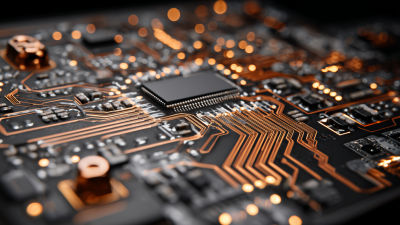

Circuit boards are often referred to as the backbone of electronic devices, playing a crucial role in their functionality. These intricate layers of material provide the necessary pathways for electrical signals, allowing components such as resistors, capacitors, and microchips to communicate effectively. Without well-designed circuit boards, even the most advanced components would fail to work harmoniously, leading to inefficiencies and potential device malfunctions. The complexity of modern electronics, from smartphones to industrial machinery, underscores the importance of precise circuit board fabrication in achieving optimal performance.

When considering circuit board design, it's essential to prioritize both functionality and manufacturability. Start by ensuring that the layout minimizes interference and optimizes signal integrity. Utilizing proper grounding techniques can significantly enhance performance, especially in high-frequency applications. Additionally, selecting materials that are suitable for the specific environmental conditions can improve the durability and reliability of the final product.

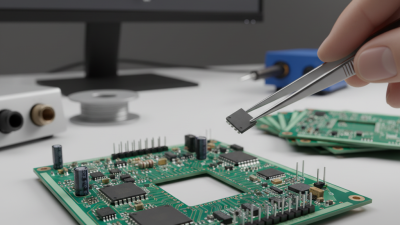

Tips: Always prototype your circuit board design before mass production to identify potential issues early in the process. Testing with real-world conditions can inform necessary adjustments for better performance. Furthermore, leverage simulations to foresee and eliminate design flaws that could impact the functionality of your electronics.

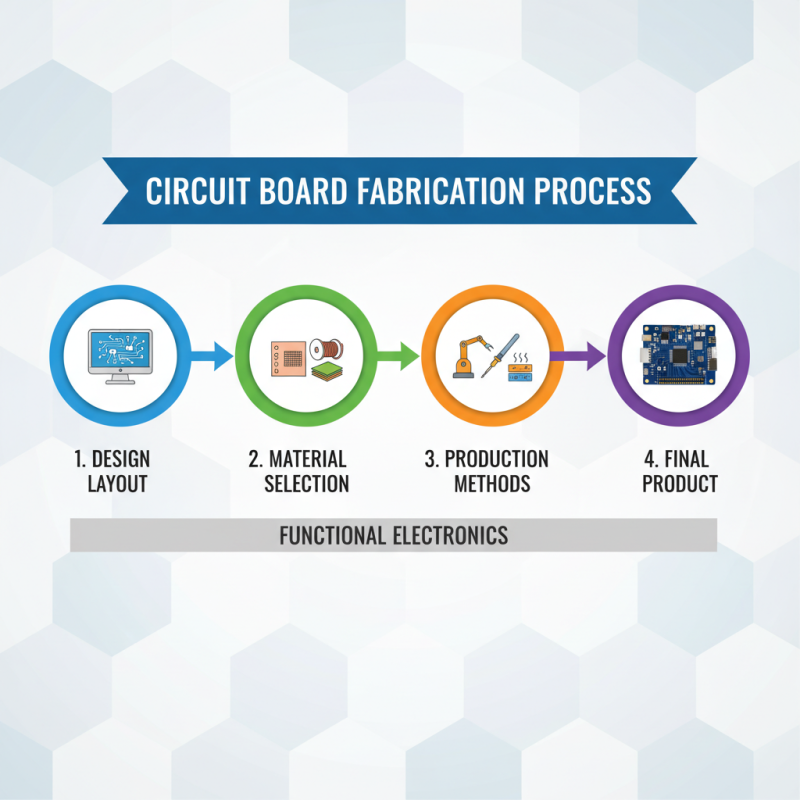

The process of circuit board fabrication plays a crucial role in the success of electronics manufacturing. Key to this process are several stages, including design layout, material selection, and production methods. It begins with designing the circuit board in a software environment, where engineers translate the intended functionality into a visual schematic. This layout guides the subsequent steps, ensuring that the final product meets the required specifications.

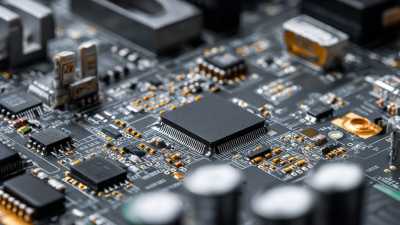

Once the design is confirmed, the selection of materials becomes vital. High-quality substrates, conductive materials, and solder masks are essential for the durability and performance of the circuit board. For instance, using FR-4 laminate ensures thermal stability and electrical insulation, which are essential for most electronic applications.

**Tips**: Always engage in thorough testing of your materials before full-scale production. This early investment in quality can save time and costs down the line.

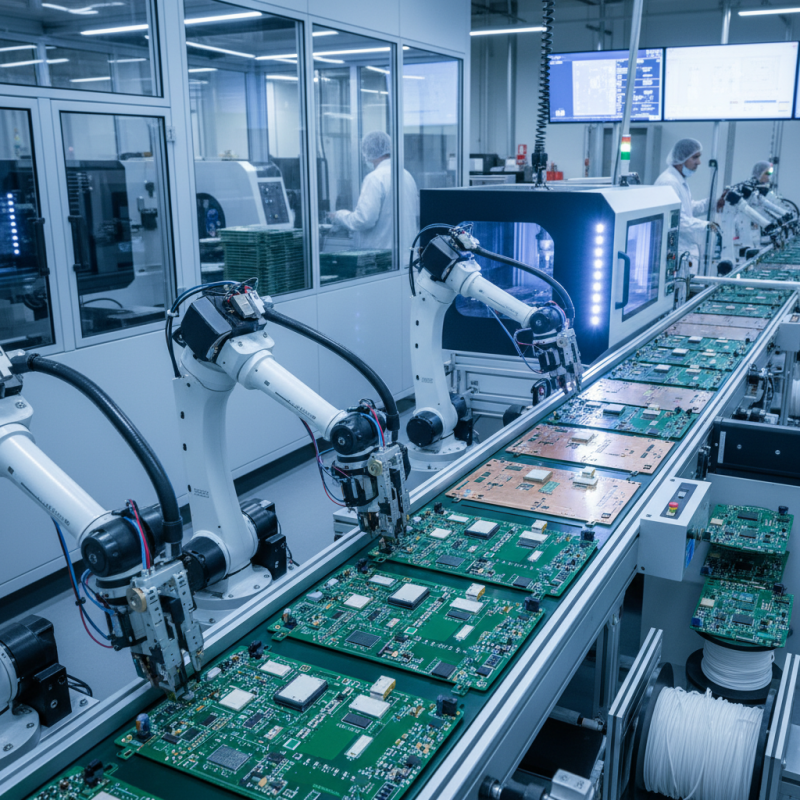

After materials are selected, the actual fabrication involves processes like etching, drilling, and assembling components. Advanced technologies such as laser etching and automated assembly lines enhance precision and efficiency, making it possible to produce complex boards quickly while reducing the potential for errors.

**Tips**: Keep refining your fabrication techniques with feedback from quality control to continuously improve the manufacturing process. Implementing regular check-ups can help catch defects early, ultimately leading to better product reliability.

The selection of materials in circuit board fabrication is paramount for achieving optimal performance in electronics manufacturing. According to a report by IPC, up to 70% of manufacturing issues can be traced back to improper material choices, underlining the critical nature of this aspect in the production process. The choice of substrate material, such as FR-4 or Rogers, affects not only the thermal and electrical properties but also the overall durability and reliability of the final product. Different applications may demand specific attributes like dielectric constant stability or high-frequency performance, making precise material selection essential.

Tip: When selecting materials, consider the specific electrical requirements and environmental conditions of the intended application. Using simulation tools during the design phase can help predict how different materials will perform under various conditions, potentially saving time and costs associated with prototype iterations.

Furthermore, factor in the manufacturing process when choosing materials. The laminating process, for example, can introduce stresses that may affect performance, especially in high-density interconnects (HDI) boards. Reports suggest that using materials with lower moisture absorption and better coefficient of thermal expansion (CTE) properties can minimize these issues.

Tip: Always test samples of your chosen materials under real-world conditions. This practical approach not only validates theoretical predictions but also provides insights that can lead to further optimization in both material selection and board design for various applications.

| Material Type | Dielectric Constant | Thermal Conductivity (W/m·K) | Glass Transition Temperature (°C) | Cost per Square Meter ($) |

|---|---|---|---|---|

| FR-4 | 4.2 | 0.3 | 130 | 15 |

| PTFE (Teflon) | 2.1 | 0.25 | 360 | 50 |

| polyimide | 3.4 | 0.25 | 300 | 75 |

| Ceramic | 6.0 | 1.5 | 500 | 100 |

| Alumina | 9.5 | 25 | 1300 | 250 |

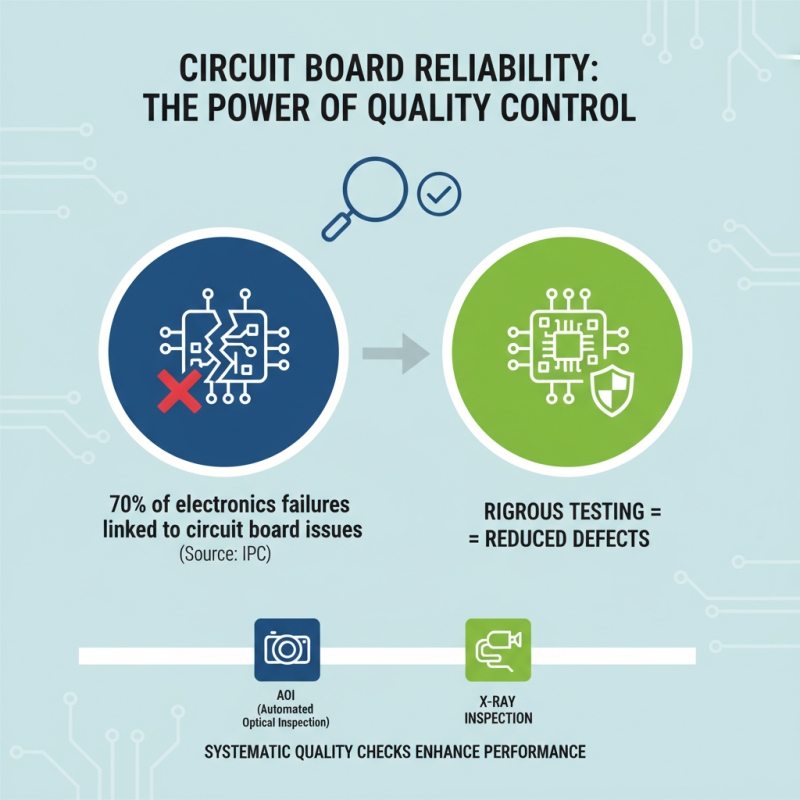

Quality control and testing are critical components in the circuit board production process, playing a pivotal role in ensuring the reliability and functionality of electronic devices. According to a report by IPC, the Association Connecting Electronics Industries, nearly 70% of failures in electronics can be traced back to issues with circuit boards. This statistic underscores the necessity for rigorous testing and quality assurance practices throughout the manufacturing process. Implementing systematic quality control measures such as Automated Optical Inspection (AOI) and X-ray inspection can significantly reduce defect rates, enhancing the overall performance of electronic assemblies.

Moreover, as the complexity of circuit board designs increases with advancements in technology, so does the need for comprehensive testing methodologies. A study conducted by the Electronics Industry Association indicates that investing in quality control can yield up to a 30% return on investment, primarily by reducing warranty claims and improving product reliability. Techniques such as in-circuit testing (ICT) and functional testing are essential to identify potential flaws before products reach the market. As manufacturers strive to meet the growing demands for high-quality, reliable electronic components, prioritizing quality control and testing in circuit board fabrication is more vital than ever for sustaining competitiveness in the electronics manufacturing industry.

The design of circuit boards plays a critical role in shaping manufacturing efficiency in the electronics industry. A well-architected circuit board facilitates streamlined production processes, reducing lead times and minimizing errors during assembly. When intricate designs are effectively executed, they not only simplify the manufacturing workflow but also enhance the scalability of production, ensuring rapid adaptation to market demands. This means that companies can react more swiftly to design changes or customer requests, maintaining a competitive edge in a fast-paced environment.

Moreover, circuit board design directly impacts the reliability and performance of the final electronic product. Efficient layouts can improve signal integrity and reduce electromagnetic interference, which are vital for the optimal functioning of electronic devices. By investing time in thoughtful design, manufacturers can prevent costly reworks and failures, as well as ensure consistency across product batches. This holistic approach to circuit board design, emphasizing both functionality and manufacturability, positions companies for greater success in meeting industry standards while keeping production costs in check.