In the realm of modern electronics, the importance of printed circuit boards (PCBs) cannot be overstated. Michael Thompson, a renowned expert in the PCB industry, once stated, “The heart of any electronic device is its printed circuit board.” This underscores the pivotal role that PCBs play in device functionality.

PCBs serve as the backbone of countless electronic devices, from smartphones to medical equipment. They provide the necessary connections for electronic components to communicate efficiently. However, the complexity of designing reliable PCBs can lead to challenges. Issues such as signal integrity and thermal management often require careful consideration.

Despite their critical role, many overlook the intricate processes involved in PCB manufacturing. Errors in design can lead to significant failures. The industry must continually reflect on these challenges to innovate and improve. Printed circuit boards are indeed essential, but they now demand a deeper understanding and greater respect in the engineering community.

Printed Circuit Boards (PCBs) play a crucial role in modern electronics. They provide the foundation on which electronic components are mounted. Without PCBs, devices like smartphones and computers would not function as we know them. These boards are designed with intricate pathways that connect various parts, allowing electricity to flow efficiently. The precision involved in PCB design is impressive. A slight mistake can lead to device malfunction.

PCBs have transformed manufacturing processes. They simplify assembly and reduce the need for cumbersome wiring. By streamlining the production of electronic devices, they have also made technology more affordable. However, the complexity involved in creating high-quality PCBs presents challenges. Engineers must carefully consider materials and layouts. If they overlook these aspects, it can lead to performance issues.

In everyday life, we often take PCBs for granted. They are hidden inside our gadgets, working tirelessly to make technology accessible. Yet, their importance cannot be overstated. As we move towards more compact and powerful devices, the demand for advanced PCB technologies grows. This evolution requires constant adaptation from engineers and manufacturers alike. Embracing innovation and addressing design flaws will be key to future advancements in electronics.

| Dimension | Description | Importance |

|---|---|---|

| Layer Count | Indicates the number of conductive layers in a board. | Higher layer counts allow for complex circuit designs. |

| Material Type | Type of substrate used like FR-4, Rogers, etc. | Affects thermal performance, signal integrity, and durability. |

| Trace Width | Width of the conductive traces on PCBs. | Impacts current carrying capacity and resistance. |

| Via Type | Different types of vias include through-hole, blind, and buried vias. | Critical for connections between layers; affects design flexibility. |

| Surface Finish | Coating on copper pads, such as ENIG or HASL. | Affects solderability and shelf life of PCBs. |

| Size | Overall dimensions of the PCB. | Determines compatibility with the end device. |

| Manufacturing Tolerance | Precision levels for dimensions and features. | Crucial for reliability and performance of electronic devices. |

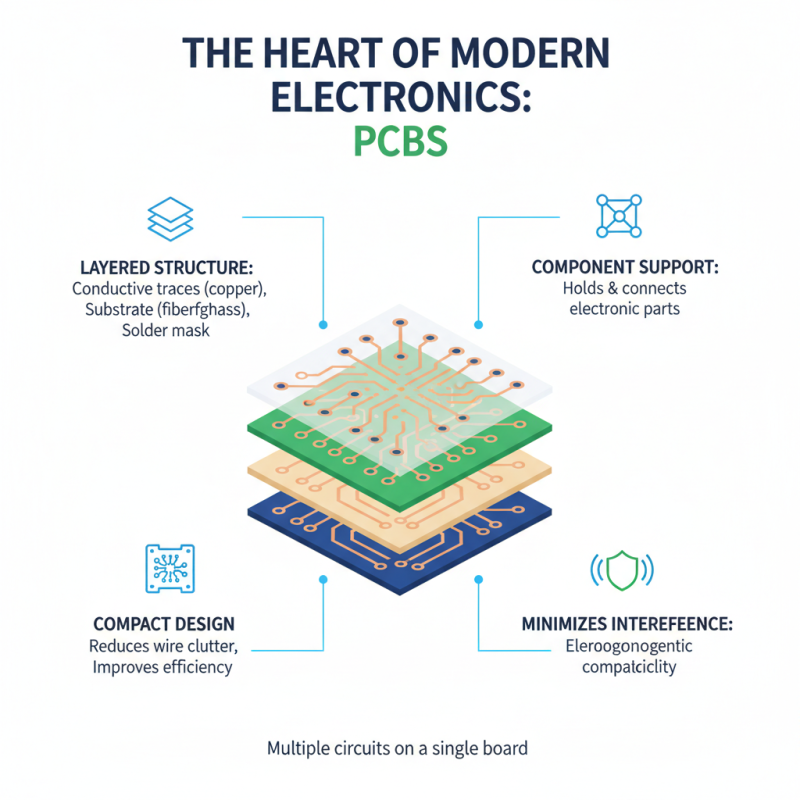

Printed Circuit Boards (PCBs) are crucial in modern electronics. Their structure is made up of layers of materials that support and connect electronic components. A simple board can hold multiple circuits, reducing the clutter of wires and improving efficiency. This compact design also helps to minimize electromagnetic interference.

The function of a PCB is pivotal. Signals flow through paths etched onto the board, connecting various components. This allows for effective communication within the device. Many devices rely on PCBs to operate smoothly, from smartphones to medical equipment.

Tips: When designing PCBs, consider the layout carefully. A well-organized layout can prevent issues. Overlapping paths may lead to signal interference. Also, use appropriate materials for your application. Not all materials are equal; they can alter performance.

Some designers overlook the need for proper testing. Testing can reveal hidden faults early in the design. It’s better to catch issues before production. Remember, even small errors can lead to big problems later. Reflect on your designs consistently. This practice can lead to significant improvements in functionality and reliability.

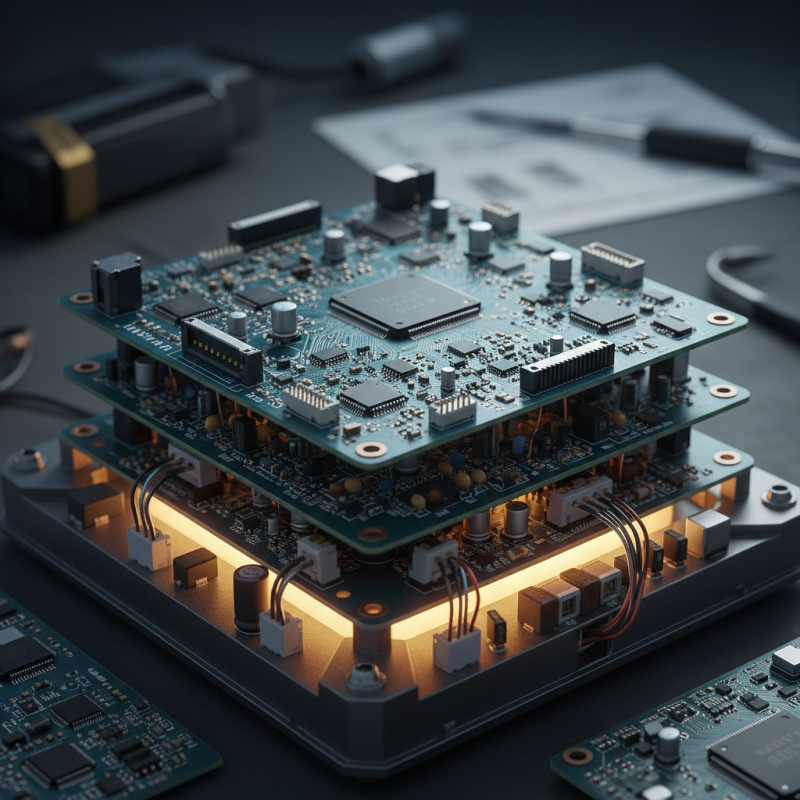

Printed Circuit Boards (PCBs) are vital for modern electronics.

They provide a compact solution for mounting electronic components. With careful design,

PCBs help save space and reduce the weight of devices. This is especially crucial in industries like aerospace

and mobile technology. The ease of integration allows engineers to create complex systems efficiently.

One major advantage of using PCBs is reliability. They ensure consistent connections while minimizing the risk of short circuits.

The layered structure can handle multiple circuits, which is crucial for multifunctional devices. However, some designs can be overly complex.

This may lead to issues during manufacturing. Simplifying design choices is often necessary for better outcomes.

Cost-effectiveness is another key benefit. PCBs can be mass-produced, lowering manufacturing costs.

This makes electronics more accessible for consumers. However, budgeting can become tricky if the design process isn’t managed well.

It's essential to weigh the initial design costs against long-term savings. Each decision in the design phase shapes how effective the final product will be.

Balancing these factors is a constant challenge for engineers.

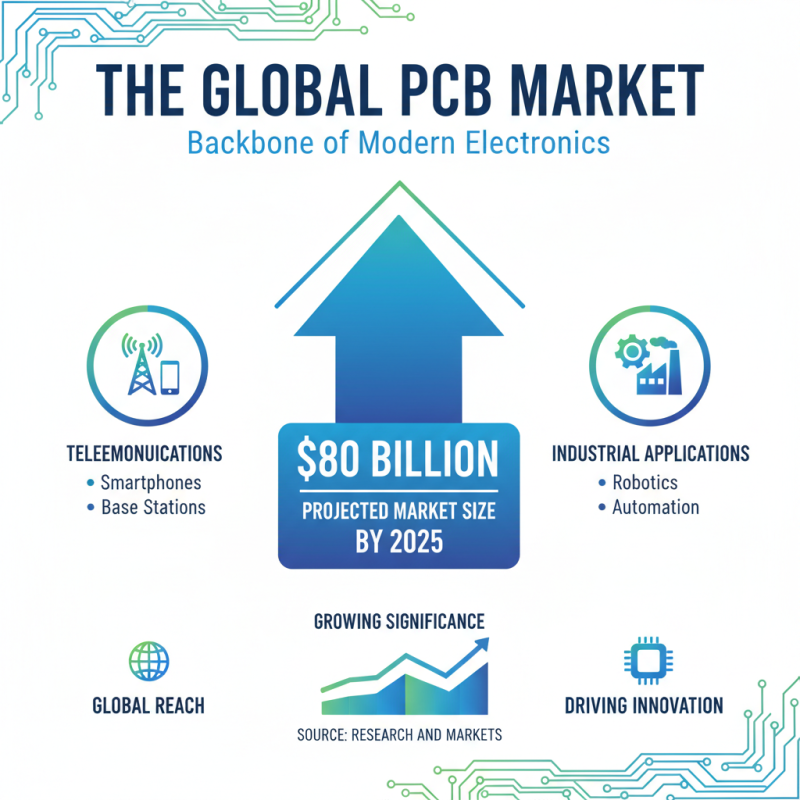

Printed Circuit Boards (PCBs) are the backbone of modern electronics. Their applications span various industries, driving innovation and efficiency. In telecommunications, PCBs are crucial for smartphones and base stations. According to a report by Research and Markets, the global PCB market is projected to reach $80 billion by 2025, highlighting their growing significance.

In the automotive sector, PCBs enable advanced navigational and safety systems. Electric vehicles rely heavily on them for managing complex circuitry. A study by Mordor Intelligence states that the automotive PCB market is expected to grow by 5% annually. This growth underscores the increasing reliance on electronics in vehicles, fueling demand for high-quality PCBs.

**Tip:** When designing PCBs, ensure to consider thermal management. Overheating can lead to failures. Additionally, always account for the layout complexity, as it can impact manufacturing costs.

In healthcare, medical devices depend on PCBs for diagnostics and monitoring systems. The precision and reliability of these components can directly affect patient outcomes. However, ensuring compliance with strict regulations can be challenging. Organizations need to continually adapt to these standards while maintaining quality.

**Tip:** Regular audits can help identify potential compliance issues. A proactive approach may save costs and time in the long run.

The importance of PCBs cannot be overstated. They are essential elements that make modern electronics function effectively, impacting our daily lives across multiple sectors. However, the complexities in design and adherence to regulations warrant careful consideration.

The future of printed circuit board (PCB) technology is brimming with innovation. Reports predict that the global PCB market will reach $100 billion by 2025, driven by the increasing demand for electronics. PCBs are a backbone for devices, from smartphones to medical equipment. As technology evolves, the need for thinner, lighter, and more efficient boards is becoming pronounced.

Recent advancements include flexible and biodegradable PCBs. These innovations can reduce electronic waste significantly. For instance, flexible PCBs can be integrated into wearable tech, making devices more user-friendly. Analysts estimate that the flexible PCB market will grow at a CAGR of 10.7% through 2028. However, challenges remain. High production costs and the complexity of materials can hinder widespread adoption.

Additionally, as 5G technology rolls out, PCBs need to handle higher frequencies. This requirement demands precision and quality, which can be difficult to achieve. Industry experts are addressing these hurdles with advanced manufacturing techniques and materials. Nonetheless, the balance between innovation and cost-effectiveness will be critical. The future of PCBs will depend on overcoming these obstacles while pushing the boundaries of what's possible.