When choosing a turnkey PCB service, several factors should be considered. In 2023, the global PCB market was valued at over $60 billion, indicating significant growth and competition within the industry. Companies often rely on turnkey PCB solutions to streamline production. This approach simplifies sourcing and manufacturing by providing a single point of contact. However, not all services offer the same level of quality or expertise.

A recent report showed that 70% of companies encountered challenges with timing and delivery in their PCB projects. It's essential to select a provider with a proven track record. Look for certifications, customer reviews, and technical capabilities. Many businesses overlook the hidden costs associated with cheap services. While affordability is attractive, it can lead to compromised quality or lengthy delays.

In today's evolving technology landscape, finding a reliable turnkey PCB service is critical. This decision can impact product timelines and overall business success. Thorough research and careful evaluation are necessary. Balancing cost, quality, and service reliability can be tricky. Yet, it’s crucial to make an informed choice for long-term success.

When selecting a turnkey PCB service provider, several key factors can heavily influence your decision. Begin with experience. Look for a provider with a proven track record in the industry. Years of service often indicate reliability and expertise. Evaluate their portfolio too. Check if they have tackled projects similar to yours.

Another critical aspect is communication. A responsive team can make a world of difference. You want to work with someone who listens to your needs. Timely updates regarding project status are essential. Quality control is also non-negotiable. Ensure the provider follows stringent quality assurance protocols.

Consider flexibility in services offered. A good turnkey PCB service should cater to different needs. From prototyping to mass production, their capability matters. Pricing structures should also be transparent. Hidden costs can lead to frustration down the line.

One common mistake is overlooking reviews. Feedback from past clients provides insights into reliability. Trust your gut, but also look at the facts. Reflect on your priorities throughout the selection process.

When selecting a turnkey PCB service, understanding manufacturing standards is crucial. PCB production requires adherence to specific certifications. According to IPC standards, compliance can significantly influence product reliability. For instance, a study by Frost & Sullivan found that over 70% of failures in electronic devices stem from poor PCB production. Ensuring your manufacturer meets these standards can mitigate risks and enhance device performance.

Tip: Always inquire about the certifications your potential PCB service holds. Look for IPC-A-610 and ISO 9001 certifications as essentials. They reflect a commitment to quality and reliability.

Quality isn't guaranteed just because a company claims to follow standards. There can be gaps in compliance due to rushed production or outdated practices. A 2021 report suggested that 60% of manufacturers faced issues maintaining consistent quality in PCB production. This inconsistency can lead to costly revisions and delays.

Tip: Visit the manufacturing facility if possible. Observing processes firsthand can provide insights into their quality control measures. Always ask about their testing protocols. A thorough understanding of their workflow can reveal hidden issues that certifications may not address.

When selecting a turnkey PCB service, balancing cost and quality is crucial. A recent industry report suggests that up to 90% of companies face challenges in meeting quality standards. Cost-cutting measures often lead to compromises, impacting the final product. Companies can easily overlook potential defects implemented during manufacturing. This can result in expensive rework or even recalls.

Quality should not be sacrificed for a lower price. In fact, research indicates that investing in higher-quality components can improve long-term reliability. Various studies show that products with high-quality PCBs demonstrate 20% fewer failures over their lifecycle. A streamlined supply chain can enhance quality but might come at a higher upfront cost. The dilemma persists: choose a lower cost with potential pitfalls or invest more upfront for better durability.

Comparing quotes from multiple providers can be misleading. Often, cheaper options come with hidden costs. Some vendors might not transparently share their manufacturing processes or quality assurance measures. This lack of clarity can raise doubts about their capability. Understanding the nuances is essential. Evaluating customer reviews and past projects can shed light on actual quality.

Be cautious; not all that glitters is gold.

When choosing a turnkey PCB service, production volume plays a critical role. It helps determine the most suitable approach for your project. Low volume runs may require different resources than mass production. Often, companies overlook this aspect, leading to unexpected costs or delays.

For low to medium production volumes, flexibility is key. A service that adapts to your needs can streamline processes. It might include a limited batch size or quick turnaround times. However, high volume production needs a more structured approach. Standardization becomes essential to ensure consistency and efficiency. Some services need better tools for high volume runs, which can slow down your project.

Evaluate your requirements carefully. Consider the technologies you need. Review the capabilities of potential services. Are they equipped for your volume? A mismatch can create hurdles. Make sure to ask questions, and don't hesitate to seek clarity. Remember that not all PCB services can handle varying production volumes effectively. Reflecting on these factors will lead to a more informed choice.

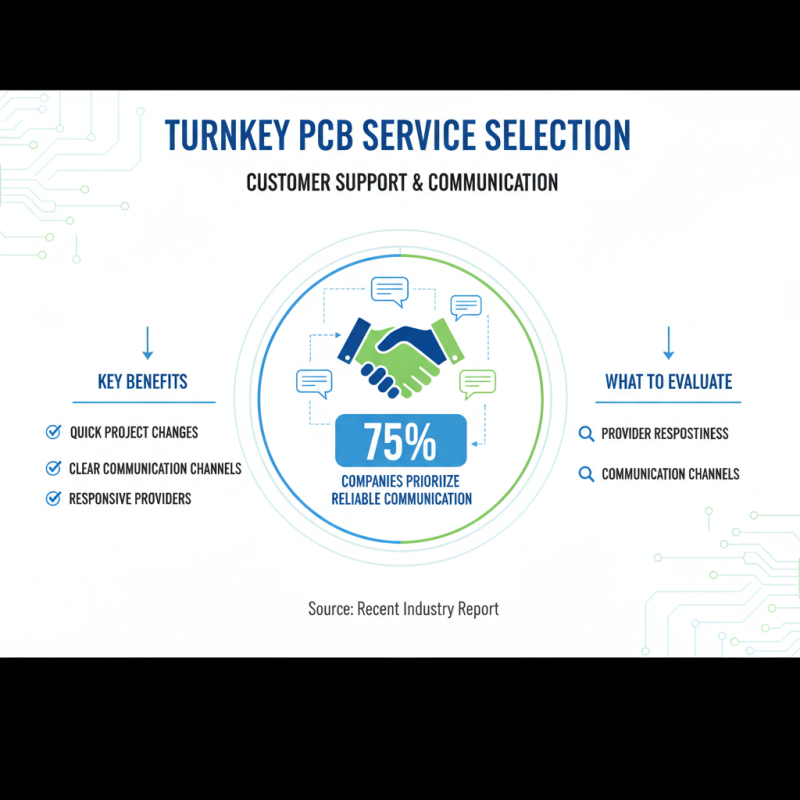

When selecting a turnkey PCB service, customer support and communication play a vital role. A recent industry report highlights that 75% of companies prioritize reliable communication when choosing a PCB supplier. Clear channels of communication ensure that any project changes are quickly addressed. It's essential to evaluate the responsiveness of potential service providers.

Before making a decision, engage with the customer support team. Ask specific questions about their process. Does their response demonstrate expertise? Speed matters; a slow reply might indicate future project delays. According to research, 60% of failed projects cite poor communication as a contributing factor. This reflects the importance of initiating dialogue early on.

Additionally, consider the available support channels. Do they offer phone, email, and chat options? Having multiple contact methods can significantly enhance the support experience. Poor customer interaction can result in misunderstandings, leading to costly errors. In the fast-paced PCB industry, choosing a partner with effective communication is not just beneficial; it's essential for project success.