The landscape of electronics manufacturing is undergoing a transformative shift, driven by innovations in PCB fab and assembly. According to a report by Research and Markets, the global PCB market is expected to reach $84.38 billion by 2027, growing at a CAGR of 4.3% from 2020 to 2027. This growth is fueled by the increasing demand for advanced electronic devices across sectors such as automotive, telecommunications, and consumer electronics.

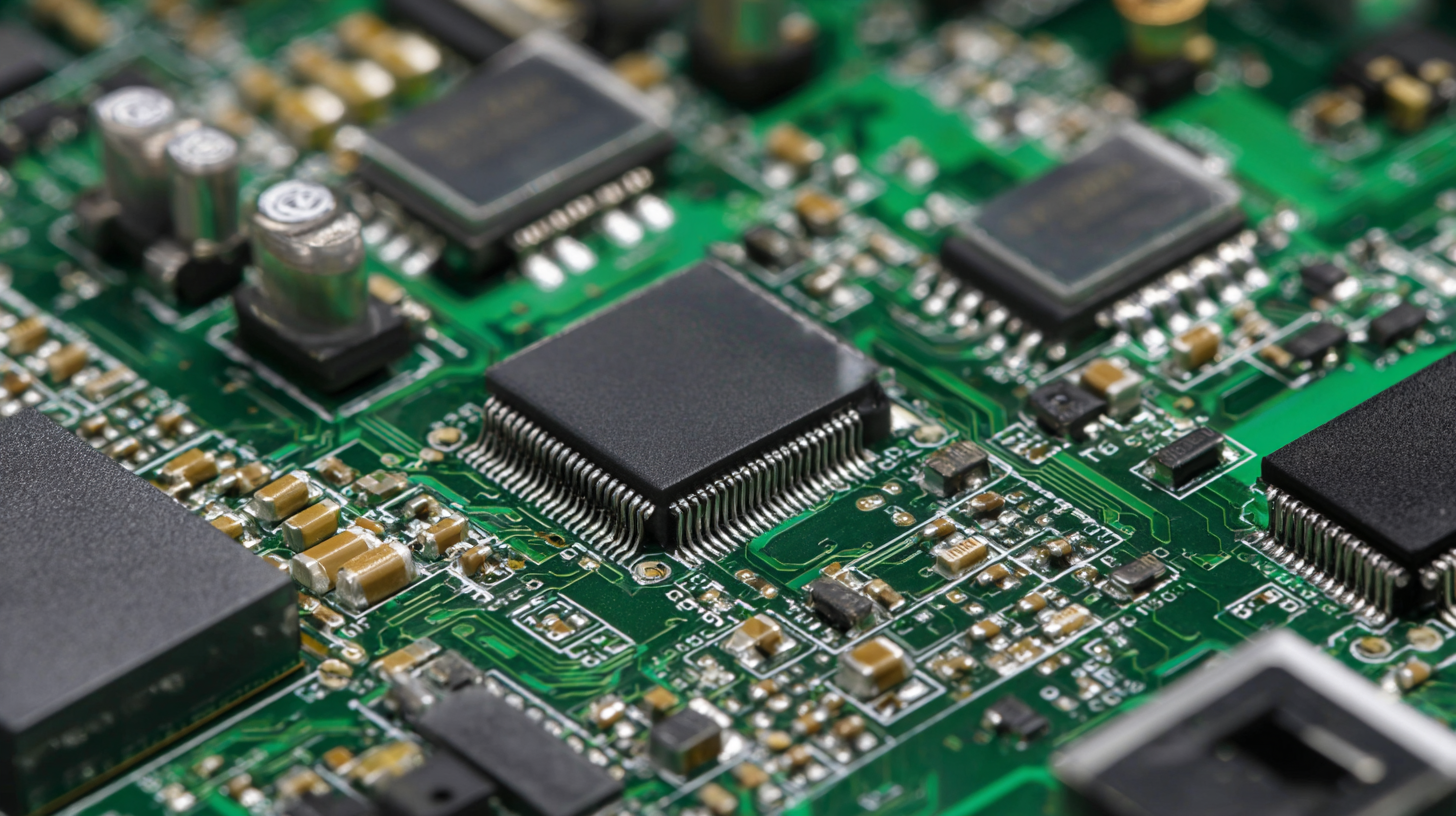

Innovations in materials and fabrication techniques, such as HDI (High-Density Interconnect) technology and additive manufacturing, are enhancing the capabilities of PCB fab and assembly processes. Furthermore, the rise of automation and IoT (Internet of Things) integration is streamlining production, elevating efficiency, and reducing time-to-market.

As the industry continues to embrace these advancements, the future of PCB fab and assembly promises significant changes that will reshape manufacturing practices, driving innovation and sustainability in the electronics sector.

The landscape of PCB fabrication is undergoing a significant transformation driven by automation and artificial intelligence (AI). According to a report by Mordor Intelligence, the global PCB market is expected to grow from $60.3 billion in 2020 to $85 billion by 2025, largely propelled by advancements in manufacturing technologies. Automation in PCB assembly streamlines repetitive tasks, reduces human error, and enhances precision. For instance, automated pick-and-place machines leverage AI algorithms to optimize component placement, reducing assembly time by up to 30%.

Furthermore, AI applications in PCB fabrication allow for predictive maintenance and real-time monitoring of production lines. A study from McKinsey & Company highlights that adopting AI technologies can improve productivity in manufacturing by up to 20%. Companies are increasingly integrating AI-driven analytics to predict failures and minimize downtime, ensuring consistent quality and reliability in the production process. As the demand for faster and more efficient manufacturing continues to rise, embracing these technological innovations becomes paramount for staying competitive in the electronics market.

This chart illustrates the projected advancements in PCB fabrication over the next five years, highlighting the impact of automation and AI on the efficiency of electronics manufacturing.

The integration of IoT and smart devices is significantly transforming the PCB manufacturing processes and assembly techniques. As more advanced embedded antenna systems emerge, including patch antennas, chip antennas, and flexible printed circuit antennas, manufacturers are compelled to innovate their production strategies. These developments cater to diverse connectivity needs such as GNSS, Wi-Fi, cellular networks, and emerging technologies like 5G, which require more sophisticated PCB designs that can handle higher frequencies and complex signal processing tasks.

Moreover, the rise of smart devices emphasizes the importance of miniaturization and integration within the PCB fabrication process. With the demand for compact and lightweight devices, manufacturers are increasingly adopting advanced assembly techniques that support higher component densities and intricate designs. This shift not only optimizes performance but also enhances the functionality of various applications, indicating that the future of electronics manufacturing will be heavily influenced by the continuous evolution of PCB technologies driven by IoT and smart device requirements.

The push for sustainability in electronics manufacturing has given rise to innovative approaches aimed at reducing the environmental footprint of printed circuit boards (PCBs). Recent studies have explored the use of lignocellulose nanofibrils (LCNF) as sustainable alternatives to traditional PCB substrates, demonstrating the potential for eco-friendly materials in this critical component of electronics. This development not only addresses the growing concerns over waste and resource depletion but also positions sustainable materials at the forefront of industry innovation.

Furthermore, new applications of recycling technologies have emerged, such as triboelectric nanogenerators fabricated from waste PCBs, which harness biomechanical energy for green hydrogen production. This highlights a transformative approach to waste management in electronics, turning potential pollutants into valuable resources.

As leading companies in the field adopt cutting-edge, sustainable practices, including PFAS-free coatings, the future of PCB fabrication and assembly promises to be more environmentally responsible while maintaining efficiency and performance in electronics manufacturing.

The PCB manufacturing industry is poised for significant growth from 2023 to 2030, driven by advancements in technology and increasing demand across various sectors, including consumer electronics, automotive, and telecommunications. According to a report by Fortune Business Insights, the global printed circuit board market is expected to reach approximately $80 billion by 2028, growing at a compound annual growth rate (CAGR) of around 4.5%. This growth is fueled by the rising integration of smart technology and automation in manufacturing processes, which improves efficiency and reduces costs.

Furthermore, the shift towards electric vehicles (EVs) and renewable energy solutions is anticipated to propel the demand for high-performance PCBs. A study by Market Research Future highlights that the automotive PCB segment alone is projected to witness a CAGR of over 5% during this period, as manufacturers adapt to increasingly sophisticated electronic systems in modern vehicles. As the electronics manufacturing landscape continues to evolve, innovation in PCB fabrication and assembly methods will play a crucial role in meeting these burgeoning demands while ensuring sustainability and efficiency in production practices.

| Year | Market Size (Billion USD) | Growth Rate (%) | Key Innovations | Main Application Areas |

|---|---|---|---|---|

| 2023 | 70 | 5.0 | Flexible PCBs, 5G Integration | Consumer Electronics, Automotive |

| 2024 | 74 | 5.7 | 3D Printing, AI Integration | Telecommunications, Medical Devices |

| 2025 | 79 | 6.8 | Automation, Smart Devices | Industrial Automation, IoT |

| 2026 | 84 | 6.3 | Eco-friendly materials | Renewable Energy, Smart Cities |

| 2027 | 90 | 7.1 | Advanced Chip Packaging | Consumer Electronics, Aerospace |

| 2028 | 97 | 7.9 | Nano-coatings | Telecommunications, Healthcare |

| 2029 | 105 | 8.2 | Smart Integration | Robotics, Smart Homes |

| 2030 | 113 | 7.5 | Augmented Reality PCBs | Entertainment, Education |

The PCB assembly industry is witnessing groundbreaking advancements that are enhancing both precision and efficiency in electronics manufacturing. State-of-the-art technologies such as automated optical inspection (AOI) and advanced soldering techniques are becoming increasingly prevalent. These innovations not only improve the accuracy of component placement but also help in detecting defects early in the production process, ultimately reducing waste and production costs significantly.

Tip: To leverage these advancements, manufacturers should consider investing in training their workforce on new technologies. A skilled team can drastically improve operational efficiency and adapt to the rapid changes in the industry.

Moreover, the integration of Industry 4.0 philosophies, which emphasize connectivity and data exchange, is reshaping PCB assembly lines. This shift enables real-time monitoring and optimization, leading to more streamlined processes. As companies adopt these smart technologies, the potential for reduced overhead costs and increased productivity becomes a reality.

Tip: Ensure that your production facility is equipped with the latest software tools that support smart manufacturing. This will enable data-driven decision making and further enhance your competitive edge in the market.