In the rapidly evolving landscape of modern electronics, the demand for faster production times has never been more critical. Fast turn PCB manufacturing stands at the forefront of this shift, enabling companies to significantly reduce their time-to-market while maintaining high-quality standards. According to a report by IPC, the global PCB market is projected to grow to $85 billion by 2024, driven by the increasing need for advanced printed circuit boards in electronic devices. This acceleration in the industry can be largely attributed to the adoption of fast turn PCB services, which facilitate quicker prototyping and testing phases. As electronic products become more complex and consumer expectations heighten, manufacturers are increasingly reliant on fast turn solutions to meet tight deadlines and enhance overall productivity. Embracing this approach not only streamlines design iterations but also fosters innovation, positioning companies to respond swiftly to market demands and technological advancements.

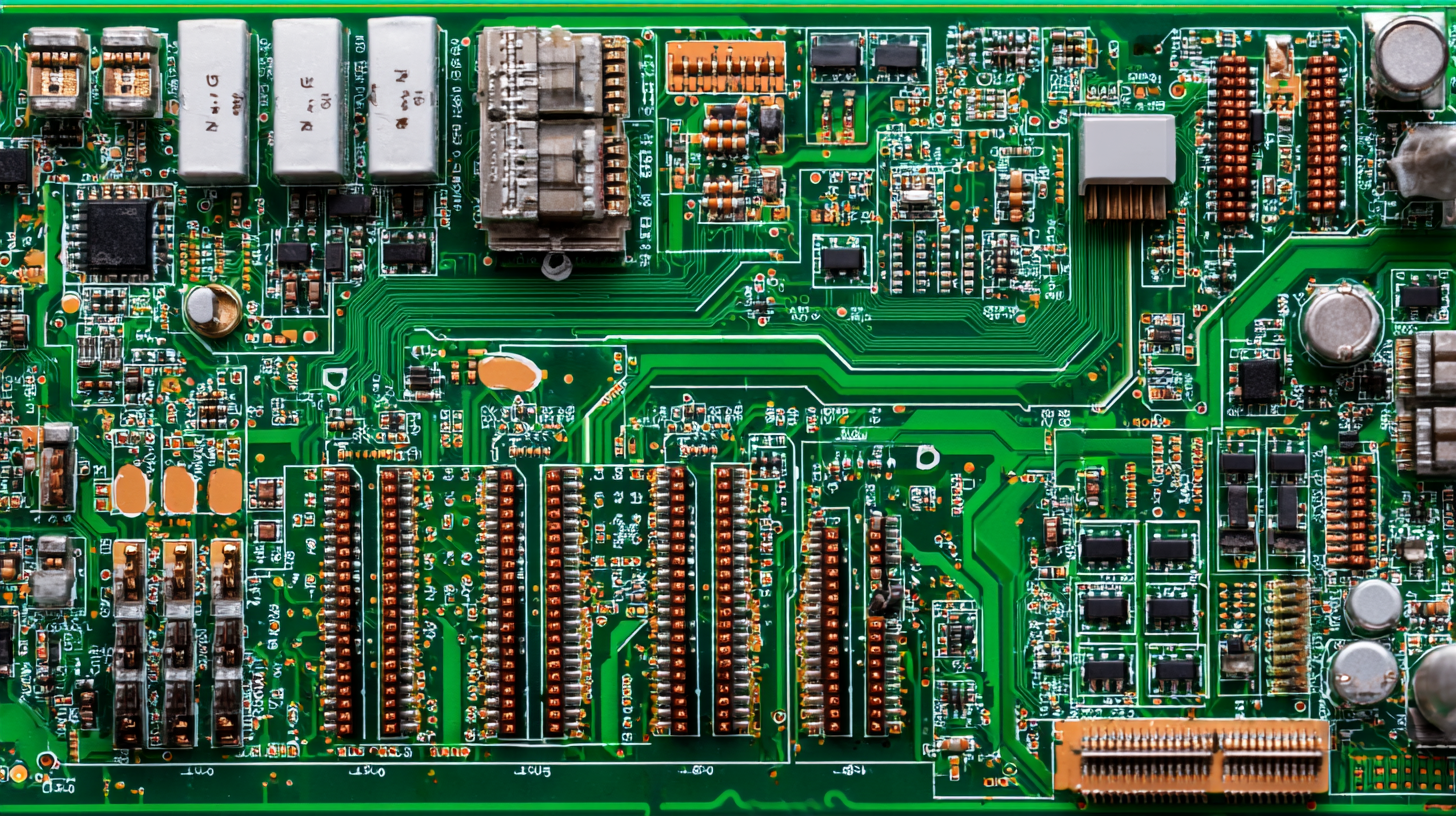

The evolution of fast turn PCB manufacturing has transformed the landscape of modern electronics. Initially, the PCB production process was characterized by long lead times and meticulous design requirements, which often delayed project timelines. However, with advancements in technology and an increasing demand for rapid prototyping, manufacturers began to optimize their processes. Enhanced techniques, such as automated assembly and streamlined materials sourcing, have enabled companies to deliver high-quality PCBs in a fraction of the time it once took.

As the market has shifted towards faster product development cycles, fast turn PCB manufacturing has become essential for electronics firms aiming to maintain competitive advantage. Producers are now equipped with state-of-the-art machinery and software that facilitate rapid design iterations and immediate production capabilities. This shift not only accelerates the release of innovative products but also allows designers to test and refine their ideas quickly, fostering a culture of creativity and efficiency within the industry. Consequently, fast turn PCB manufacturing is no longer just a luxury but a vital component of modern electronics development strategies.

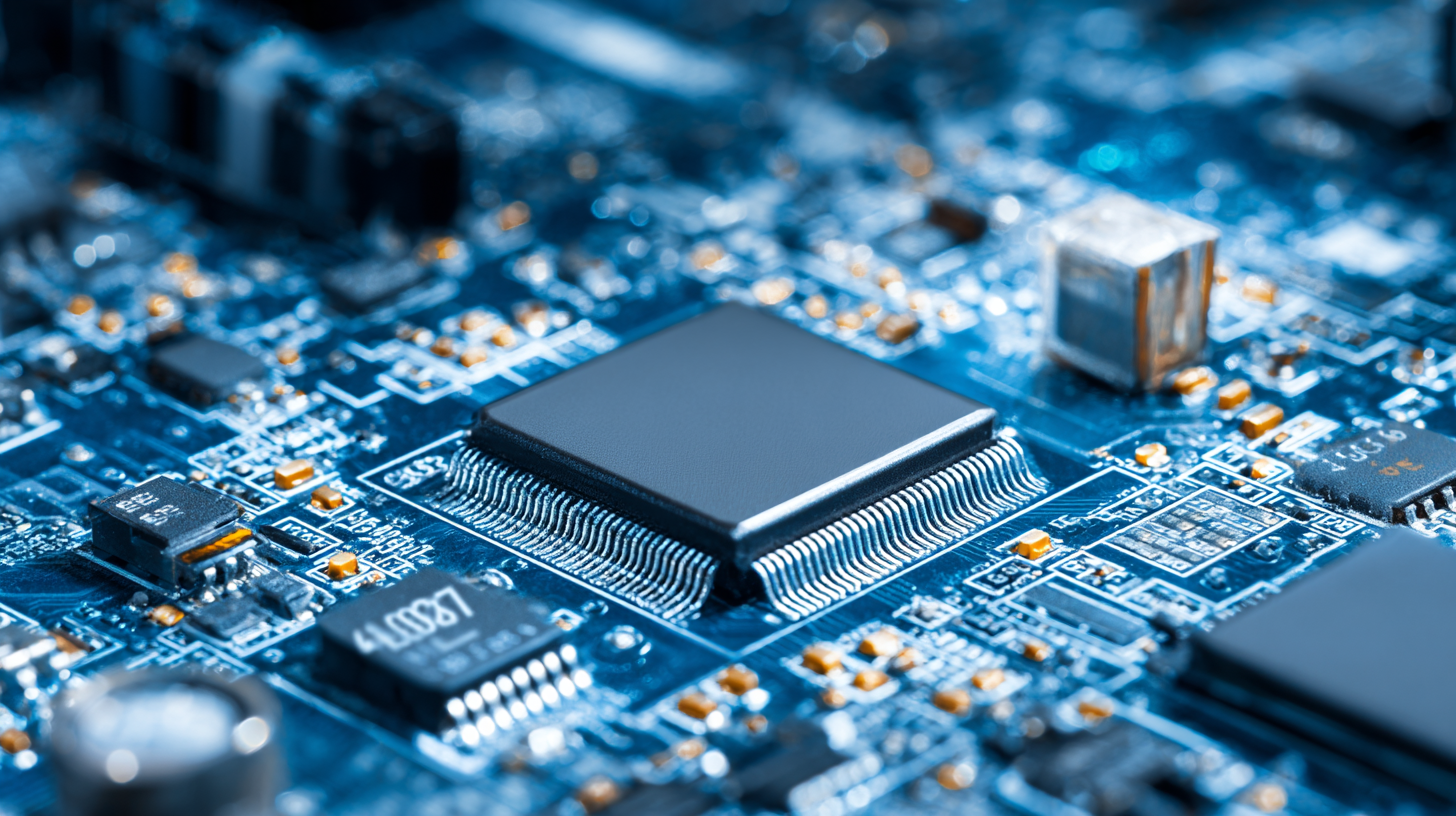

Rapid PCB prototyping and production have been revolutionized by several key technologies that enhance efficiency and reduce time-to-market for modern electronics. One of the most significant advancements is the introduction of high-speed CNC machining and laser cutting, which allow for precise and swift fabrication of PCB prototypes. These methods not only ensure high accuracy but also minimize material waste, making them environmentally friendly while meeting the growing demand for rapid turnaround.

Another critical technology is the adoption of automated assembly processes, such as pick-and-place machines, which can position components on the PCB with remarkable speed and precision. This automation streamlines production lines, significantly decreasing labor costs and the potential for human error. Coupled with advanced materials like flexible substrates and multilayer constructions, these innovations enable manufacturers to produce complex designs that cater to the intricate needs of modern electronics, from consumer gadgets to sophisticated industrial devices.

Fast turn PCB services have become crucial in today's fast-paced electronics landscape, significantly accelerating product development cycles. By enabling quicker prototyping and assembly, these services empower companies to bring innovative solutions to market faster, adapting swiftly to changing consumer demands. For example, firms like Tempo Automation are making strides in streamlining electronics manufacturing, further reducing the time from concept to production.

To maximize the benefits of fast turn PCB services, consider implementing integrated design tools and agile project management methodologies. These approaches facilitate collaboration among teams and enhance communication, ensuring that any potential roadblocks are addressed promptly. Additionally, leveraging advanced technologies such as AI-driven optimization can lead to improved PCB layouts, increasing the efficiency of the production process.

Moreover, partnering with comprehensive service providers can provide valuable resources for rapid prototyping. Companies like Shenzhen Tengxinjie exemplify the potential of one-stop production services, which not only save time but also maintain high-quality standards throughout the manufacturing process. Embracing these strategies is essential for any organization looking to stay competitive in the evolving electronics sector.

In today's fast-paced electronics market, the benefits of quick turnaround in PCB manufacturing cannot be overstated. Rapid prototyping and fast turn PCB services significantly reduce time-to-market, allowing companies to respond swiftly to consumer demands and technological advancements. This efficiency not only enhances competitiveness but also enables innovators to launch new products, gather customer feedback, and iterate designs more rapidly.

Furthermore, as seen in the cross-border e-commerce sector, where logistics timing is crucial, timely delivery capabilities are shaping brand success. Establishing overseas warehouses allows businesses to stock products closer to their target markets, reflecting the growing expectation for immediate product availability. In a similar vein, quick turn PCB manufacturing provides electronics companies with the agility needed to keep pace with an evolving industry landscape, ensuring they remain leaders in innovation and customer satisfaction.

This bar chart illustrates the average time-to-market for electronics using traditional manufacturing versus quick turn PCB manufacturing. As depicted, quick turn PCB manufacturing significantly reduces the time-to-market, enhancing efficiency and responsiveness in the electronics industry.

The fast turn PCB manufacturing process presents a series of challenges that modern electronics companies must navigate to maintain efficiency. According to a report by PCB Research, approximately 60% of manufacturers experience delays in time-to-market due to production inefficiencies. These inefficiencies often stem from complex supply chains, outdated machinery, and insufficient skilled workforce. A significant hurdle is the design-for-manufacturing (DFM) phase, where late changes can lead to increased costs and longer production times. Manufacturers are increasingly adopting advanced simulation tools to streamline this phase, allowing for real-time adjustments and minimizing potential disruptions.

Moreover, quality control remains a critical challenge in fast turn PCB production. A recent industry survey revealed that nearly 30% of fast turn PCBs suffer from defects, primarily due to rushed inspections and inadequate testing procedures. To address this issue, companies are investing in automated inspection technologies like Automated Optical Inspection (AOI) and X-ray systems, which enhance precision and reduce the margin for error. Additionally, establishing robust vendor relationships can ensure a more reliable supply chain, further facilitating faster turnaround times without compromising on quality. By leveraging these solutions, manufacturers can unlock greater efficiency and responsiveness in the competitive landscape of modern electronics.