In the rapidly evolving landscape of technology, the significance of circuit board manufacturing cannot be overstated. As Jeffrey W. Smith, a leading expert in the field and CEO of Advanced PCB Solutions, aptly puts it, "Circuit board manufacturing is the backbone of modern electronics, enabling innovative designs and functionality."

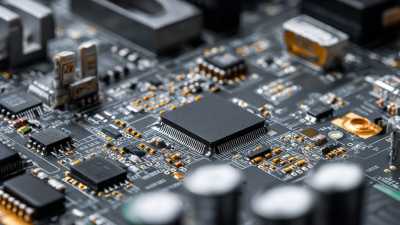

The intricate process of producing printed circuit boards (PCBs) serves as the foundation for virtually every electronic device we rely on today, from smartphones to medical equipment.

The intricate process of producing printed circuit boards (PCBs) serves as the foundation for virtually every electronic device we rely on today, from smartphones to medical equipment.

Understanding the vital role of circuit board manufacturing sheds light on the latest advancements in the industry and the impact of emerging technologies. With the increasing complexity of electronic devices, manufacturers are continually forced to innovate and enhance production techniques to meet demanding specifications. This not only ensures the reliability and efficiency of electronic components but also drives the entire tech ecosystem forward.

In this article, we will explore the critical importance of circuit board manufacturing in the modern world, discussing the challenges and opportunities that lie ahead. By delving into expert insights and industry trends, we aim to provide a comprehensive overview of why circuit board manufacturing is essential for the future of electronic devices and what that means for consumers and manufacturers alike.

Circuit boards are at the core of modern electronic devices, serving as the backbone that interconnects various components and facilitates communication between them. As we approach 2025, the evolution of technology demands that circuit boards become increasingly sophisticated. With the rise of the Internet of Things (IoT) and smart devices, advanced circuit board manufacturing is essential to support the high-speed data transmission and processing capabilities required for these innovations.

Moreover, the shift towards miniaturization in electronics places greater emphasis on efficient circuit board design and production. As devices become smaller and more powerful, circuit boards must be engineered to fit into compact spaces without compromising functionality. This necessity drives advancements in materials and manufacturing techniques, leading to lighter, more efficient, and cost-effective solutions. The role of circuit boards will be pivotal in unlocking the full potential of next-generation electronics, ensuring that they meet the demands of consumers and industries alike.

| Dimensional Aspect | Statistics | Importance |

|---|---|---|

| Global Circuit Board Market Size (2023) | $66 Billion | Foundation for all modern electronics |

| Projected Growth Rate (2025) | 4% CAGR | Indicates increasing demand for electronic devices |

| Number of Layers in PCBs (Commonly) | 2-10 Layers | Increased complexity supports advanced functionality |

| Average PCB Development Time | 4-6 Weeks | Critical for rapid innovation cycles |

| Recycling Rate of PCBs | 20% | Impacts sustainability efforts in electronics |

The global circuit board market is projected to witness significant growth, driven by increasing demands from various sectors, particularly in consumer electronics and automotive applications. According to recent studies, the printed circuit board (PCB) market is set to expand by approximately USD 26.8 billion between 2025 and 2029, emphasizing the pivotal role of circuit boards in modern electronic devices. Additionally, the flexible printed circuit boards market is expected to grow dramatically from USD 27.2 billion in 2025 to an estimated USD 98.1 billion by 2035, reflecting innovation and adaptability in design.

Tips for Maximizing Investment in Circuit Board Manufacturing:

Investing in advanced manufacturing technologies can significantly enhance efficiency and product quality. Staying updated with trends such as miniaturization and AI integration can give manufacturers a competitive edge. Emphasizing sustainability in manufacturing processes not only meets regulatory demands but also appeals to environmentally conscious consumers, thereby broadening market reach.

As industries evolve, the demand for high-density interconnect (HDI) PCBs is on the rise, with projections estimating the market will surpass USD 19.59 billion by 2025. Companies should focus on developing strategic partnerships and diversifying their product ranges to cater to this growing need efficiently.

Innovations in circuit board manufacturing are transforming the landscape of consumer electronics. As technology continues to advance, the demand for more efficient, high-performance printed circuit boards (PCBs) is on the rise. One of the notable trends is the increasing adoption of offline laser depaneling systems, projected to reach a market size of $203.26 million by 2032. This technology, which encompasses UV and green laser systems among others, enhances precision and efficiency in PCB production, facilitating quicker turnaround times and improved product quality.

In the realm of PCB prototyping, companies are urged to consider critical factors such as delivery time, technical expertise, and service quality. The ability to meet market demands swiftly while ensuring high standards is crucial in maintaining a competitive edge in the electronics sector. As consumer electronics evolve, innovations in circuit board manufacturing will play a central role in bolstering the industry's growth, especially with the upcoming electronic semiconductor industry conference and exhibition anticipated to showcase further advancements and foster collaborations within this dynamic market.

Sustainability in circuit board production is gaining increasing attention within the electronics industry. As the demand for electronic devices continues to grow, manufacturers are recognizing the importance of integrating eco-friendly materials and practices into their processes. Many current initiatives focus on regulatory compliance, yet true environmental responsibility goes beyond mere adherence to laws. Companies are increasingly seeking innovative ways to reduce waste, utilize sustainable materials, and enhance energy efficiency throughout the circuit board manufacturing lifecycle.

Moreover, sustainability challenges are on the horizon. The need for advanced analytics to optimize production processes is becoming apparent, especially as the focus shifts towards minimizing the ecological footprint of manufacturing. For instance, initiatives that promote the responsible sourcing of raw materials are becoming critical as industries such as mining and electronics converge to meet the rising demand for essential components. As organizations strive to achieve their sustainability goals, the concerted effort between technology advancement and environmentally friendly practices will play a pivotal role in shaping the future of circuit board manufacturing, ensuring that the industry can support economic, environmental, and social processes in a sustainable manner.

The surge of 5G technology is profoundly influencing circuit board design and manufacturing processes. As the demand for faster communication networks grows, circuit boards need to accommodate higher frequencies and increased data handling capabilities. This shift necessitates innovations in materials and manufacturing techniques, particularly as we see a rise in flexible printed circuit boards (PCBs) that cater to the miniaturization of electronic devices. The flexible PCB market is projected to expand significantly, reflecting a broader trend toward compact and highly functional electronic systems.

**Tips:** When considering circuit board design, prioritize heat dissipation characteristics to enhance reliability. Additionally, invest in advanced software tools that facilitate the design of multilayer boards, ensuring compliance with the latest 5G requirements. Keeping abreast of manufacturing trends, such as sustainable practices and AI-assisted design, can also position your business to capitalize on the evolving electronics landscape.

Thailand is emerging as a pivotal player in the PCB manufacturing space, with substantial investments contributing to its growth as a regional hub. This evolution indicates a shift in the global supply chain, influencing how businesses approach PCB sourcing and production methods in an increasingly interconnected market. Companies need to align their strategies with the trends shaping the industry to remain competitive.