In today's rapidly evolving electronics landscape, the demand for quick turn flex PCB technology is on the rise. Industry expert Dr. Emily Chen, a leader in flexible circuit design, emphasizes its importance: “Quick turn flex PCBs enable faster innovation and adaptability in device design.” This technology allows companies to produce flexible printed circuit boards with shortened lead times, responding swiftly to market needs.

Designed for high performance, quick turn flex PCBs are not only lightweight but also space-efficient. They provide enhanced durability, essential for modern electronics that face harsher environments. The ability to integrate these circuits into complex shapes opens new doors for product design. However, some manufacturers grapple with achieving optimal reliability in high-stress conditions.

While quick turn flex PCBs promise many benefits, challenges remain. Companies must balance speed with quality, often finding trade-offs that require careful consideration. This is where the insights from experts like Dr. Chen become invaluable, guiding the industry towards solutions that meet both standards and demands. As the technology continues to advance, embracing these complexities will be crucial for sustained success in electronics.

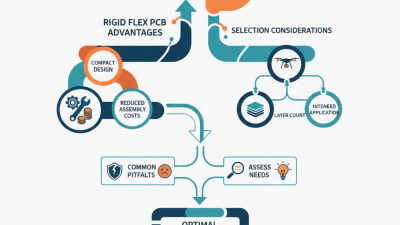

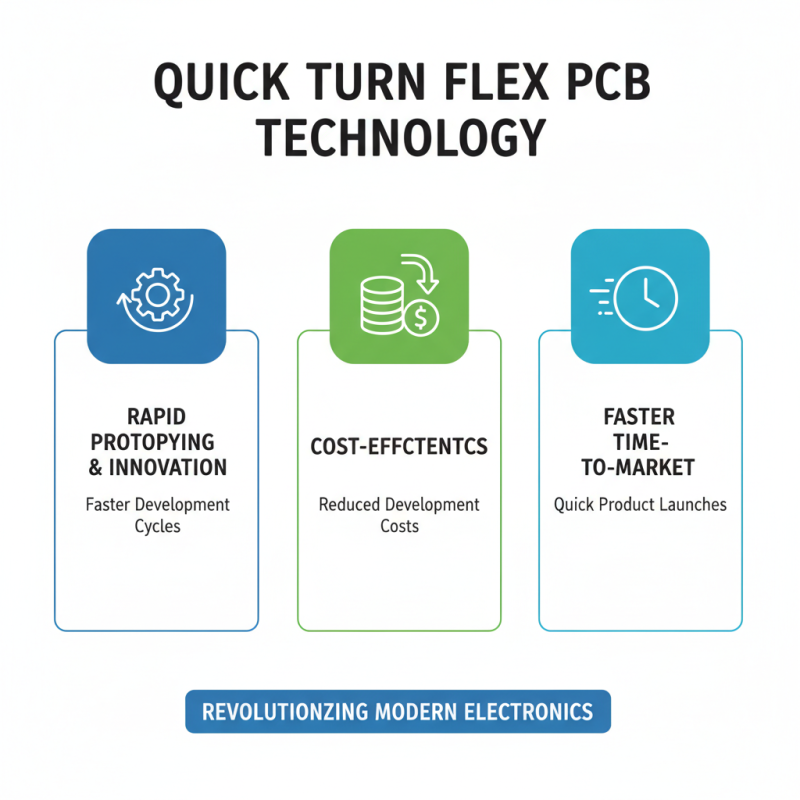

Quick turn flex PCB technology offers significant advantages for modern electronics. This method allows for rapid prototyping and production. Designers can create flexible circuits that conform to various shapes and sizes. This flexibility leads to innovative designs that traditional rigid boards cannot achieve. Richer functionalities can be integrated into smaller devices, catering to the growing demand for compact electronics.

In addition to design flexibility, quick turn flex PCBs can reduce time-to-market. Speedy production cycles help companies stay competitive. However, maintaining quality in such rapid processes can be challenging. Constant adjustments to designs may lead to inconsistencies. Additionally, while quick turn capabilities are essential, they can sometimes compromise long-term reliability if not managed well. Striking the right balance is crucial for successful implementation.

Quick turn flex PCB technology has transformed the way we approach rapid prototyping in modern electronics. This innovation enables designers to quickly iterate on their concepts. Speed is a significant advantage. Projects that used to take weeks can now be completed in days. This rapid turnaround can be a game changer for engineering teams working under tight deadlines.

Flex PCBs are lightweight and adaptable. They can be easily bent and folded, allowing designs in compact spaces. This flexibility fosters creativity, enabling engineers to explore more complex shapes. Despite these advantages, engineers must remain aware of material limitations. Not all components may perform well in extreme conditions, like high temperatures. Testing is essential. Each design iteration requires careful validation to ensure reliability.

Moreover, the quick turn process may lead to unexpected challenges. Tighter timelines can result in overlooked details, pushing teams to balance speed with quality. Communication within the team becomes critical to avoid mistakes. In rapid prototyping, understanding the nuances of each design can make all the difference. Fine-tuning this balance is a continuous journey for many engineers.

This bar chart illustrates the key advantages of Quick Turn Flex PCB technology for rapid prototyping in modern electronics. The data represents five significant benefits and their perceived importance in the industry.

The rise of quick turn flex PCB technology has transformed modern electronics. Designers now enjoy greater freedom in creating compact devices. This flexibility allows for intricate layouts that fit various shapes and sizes. Such adaptability is crucial for industries demanding miniaturization.

Moreover, flexible PCBs enable smaller components to be integrated seamlessly. This leads to lighter devices with improved performance. The ability to bend and twist PCBs opens avenues for innovative designs. However, the challenge lies in maintaining reliability in complex configurations. Engineers must carefully assess material choices and manufacturing processes.

Feedback from users often highlights the importance of durability and cost. They appreciate the convenience of rapid prototyping, yet worry about long-term performance. Balancing flexibility and reliability is an ongoing task. As technology advances, continual reflection on these aspects will drive future innovations.

Quick turn flex PCB technology is revolutionizing modern electronics, especially regarding cost-effectiveness. Companies are under constant pressure to innovate while keeping costs low. Quick turn flex PCBs allow for rapid prototyping. This feature reduces development time, allowing faster product launches. The shorter lead times can also lead to significant savings.

Using quick turn flex PCBs often means less waste. Traditional PCB methods can lead to excess materials and longer testing cycles. Quick turn processes streamline production. This can lead to a more efficient use of resources. However, some manufacturers may overlook the importance of quality control during rush production. It is essential to maintain high standards even when time is short.

**Tip:** Always verify the specifications before placing an order. Small mistakes can lead to significant delays. Adopt a collaborative approach when working with suppliers. This helps in aligning expectations and ensuring clarity throughout the process. Balancing speed and quality is crucial. In the quest for cost-effectiveness, do not sacrifice the core values of reliable performance.

Quick turn flex PCB technology has emerged as a game-changer in various industries. This technology allows for rapid prototyping and production of flexible printed circuit boards. In sectors like automotive and aerospace, quick turn flex PCBs reduce time-to-market significantly. For instance, the automotive sector saw a 25% acceleration in product development cycles, according to a recent industry report.

In medical devices, quick turn flex PCBs enable miniaturization of components. This is crucial for wearable health monitors and diagnostic equipment. These devices often include sensors that require compact designs. A study showed that flexible PCBs can cut down device size by as much as 40%. However, one must ensure the reliability of these boards under different conditions.

While quick turn flex PCBs offer many benefits, there are challenges. The cost can be higher than traditional rigid PCBs, particularly for smaller batches. Ensuring high-quality production can be difficult when scaling. Some manufacturers report inconsistent performance in heat dissipation. These factors urge continuous evaluation of design choices in complex applications. Consideration of environmental impacts and testing for durability also remains vital in the design process.

| Benefit | Description | Applications |

|---|---|---|

| Cost Efficiency | Reduced manufacturing costs due to less material waste and efficient production processes. | Consumer Electronics, Medical Devices |

| Rapid Prototyping | Accelerates the design process with quick turnaround times for prototypes. | Aerospace, Robotics |

| Space Saving | Flexible design allows for compact layouts in limited spaces. | Wearable Technology, Mobile Devices |

| Improved Reliability | Enhanced durability and flexibility reduce the risk of mechanical failures. | Industrial Automation, Automotive |

| Versatile Applications | Suitable for a wide range of electronic applications due to its adaptability. | Telecommunications, Defense |