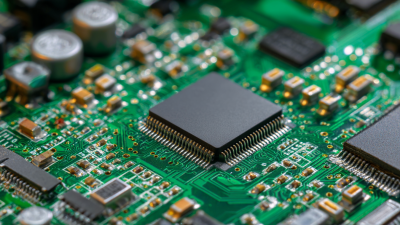

In today's fast-paced electronics landscape, the demand for rapid prototyping solutions continues to grow, with quick turn PCB services becoming increasingly essential for businesses looking to stay competitive. According to a recent report from the IPC (Association Connecting Electronics Industries), the global PCB market is set to reach $82 billion by 2025, driven in part by the rising need for speedy and cost-effective production methods. Quick turn PCB services offer manufacturers the ability to produce prototypes within a remarkably short timeframe, often as little as 24 hours, enabling faster design iterations and shorter time-to-market for new products.

The rise of the Internet of Things (IoT) and the demand for sophisticated electronics have further amplified this trend, where efficient turnaround times are crucial for innovation. A study by Market Research Future predicts that the global IoT market will exceed $1 trillion by 2025, underscoring the importance of quick turn PCB capabilities that can support rapid advancements in technology. As companies are increasingly focused on agile development practices, selecting the right quick turn PCB service provider becomes critical to achieving these goals while maintaining high standards of quality and performance in their electronic designs.

Rapid PCB prototyping has become an essential part of the product development landscape, catering to industries eager to bring innovations to market swiftly. According to a recent report by MarketsandMarkets, the global PCB market is expected to grow from $60.3 billion in 2022 to $80.5 billion by 2027, fueled largely by demand for faster prototyping solutions in electronics. The pressure on companies to reduce time-to-market has led to an increased dependence on quick-turn PCB services, which can offer turnaround times as short as 24 hours for prototype production.

Companies like JLCPCB and PCBWay are leading the charge in providing these rapid services, leveraging advanced manufacturing technologies and streamlined processes. These providers ensure high-quality output while maintaining competitive pricing and fast delivery timelines. For instance, JLCPCB boasts capabilities of producing PCBs in just one day, demonstrating their commitment to meeting the needs of engineers and developers who require quick iterations for testing and final product development. As the demand for innovation continues to rise, the rapid prototyping PCB services are poised to play a critical role in shaping the future of electronics.

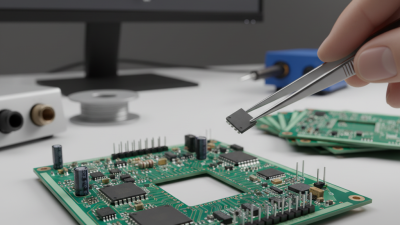

When selecting quick turn PCB services for fast prototyping solutions, there are several key features to consider that can significantly enhance the efficiency of the design and manufacturing process. First and foremost, a comprehensive service offering is crucial. Providers that facilitate the entire journey from design to production can streamline workflows, reducing the time and effort needed to transition from concept to prototype.

Access to advanced design tools and skilled engineers can empower teams to iterate quickly and effectively resolve any design challenges.

Additionally, a commitment to low-volume production can provide valuable flexibility for engineers working on prototypes. This allows for testing and validation of designs without committing to large production runs, which is especially beneficial for startups and R&D teams seeking to refine their products.

Quality assurance and adherence to industry standards are also vital; choosing a service that prioritizes high manufacturing quality can lead to improved performance and reliability of the final product. Lastly, faster turnaround times, often facilitated by localized manufacturing capabilities, can significantly reduce time-to-market, allowing companies to stay competitive in a rapidly evolving industry.

Prototyping is a crucial stage in product development, and selecting an efficient PCB service can significantly influence both the quality of the end product and the speed of production. When considering quick turn PCB services, cost efficiency becomes paramount. Companies must find a balance between the expenses associated with fast prototyping and the quality of materials and workmanship involved. A lower price might seem attractive, but it often comes at the risk of subpar components that could compromise the overall performance of the prototype.

Furthermore, evaluating a service provider's reputation for quality is essential in the decision-making process. Reliable quick turn services leverage advanced technology and proficient staff to deliver high-quality results within tight deadlines. Investing in a reputable service can save money in the long run by minimizing the risk of errors and rework. Therefore, it's vital for businesses to carefully assess their prototyping needs, considering both speed and quality, to ensure they achieve the best possible outcome without exceeding their budget.

When selecting a quick turn PCB provider, it's essential to consider several key factors that can impact the quality and speed of your prototyping solutions. According to recent industry reports, the efficiency of PCB manufacturers can vary significantly, with lead times ranging from just 24 hours to several weeks depending on their capabilities. A reliable provider should offer expedited services while maintaining high quality standards to meet the fast-paced needs of electronic design.

In choosing the right manufacturer, look for one that specializes in PCB assembly and has demonstrated expertise in rapid prototyping. Data shows that providers with advanced technology and streamlined processes are more likely to deliver consistent, repeatable results. Reviewing customer feedback and case studies can provide insights into a manufacturer's reliability and performance. Additionally, consider their material sourcing and soldering techniques, as these factors greatly influence the final product quality, particularly in high-frequency applications. A well-chosen partner can significantly enhance your product development cycle and overall project success.

When ordering fast PCB prototypes, it's crucial to sidestep common pitfalls that can derail even the best-laid plans. One frequent mistake is not fully understanding the specifications required for the project. Many designers overlook critical parameters such as layer count, material types, or copper thickness, which can significantly impact the performance and quality of the prototype. Before placing an order, it’s advisable to double-check the design files and confirm compatibility with the manufacturer's capabilities.

Another common oversight involves timeline miscalculations. While many quick-turn PCB services promise rapid delivery, the actual turnaround can be influenced by several factors, including complexity and volume of the order. Designers often assume all prototypes will be ready within the same timeframe, leading to delays that can affect project timelines. Proper communication with the PCB manufacturer about realistic lead times and potential bottlenecks is essential to ensure timely delivery of prototypes.

This chart illustrates the turnaround times for various quick turn PCB services, highlighting the differences in efficiency among the top providers. Selecting a service with optimized turnaround times can significantly enhance prototyping processes.