In the rapidly evolving world of electronics, the importance of choosing the right PCB fab company for your next project cannot be overstated. Industry expert Dr. Emily Chen, a renowned authority in printed circuit board manufacturing, emphasizes that "the quality of your PCB fab can significantly affect the overall performance and reliability of your electronic devices." With countless options available, navigating the landscape of PCB fabrication can be daunting for engineers and designers alike.

This article aims to shed light on the top 10 PCB fab companies that you need to know to ensure your next project is successful. From innovative technologies to exceptional customer service, these companies have established themselves as leaders in the PCB fab industry. Understanding their unique strengths will help you make informed decisions when seeking manufacturing partners for your electronic projects. We will explore their capabilities, industry footprints, and what sets them apart in a competitive market, setting the stage for a fruitful collaboration that could enhance your project's outcome.

The PCB fabrication industry is a critical segment of the electronics supply chain, playing a vital role in the development of modern technology. This sector is characterized by a diverse range of companies that specialize in manufacturing printed circuit boards, catering to various industries including consumer electronics, automotive, telecommunications, and medical devices. As technology advances and the demand for smaller, more complex electronic devices grows, the PCB fabrication industry continues to innovate, adopting cutting-edge materials and manufacturing techniques to meet these challenges.

Competition within the PCB fabrication industry is intense, with an increasing emphasis on quality, speed, and cost efficiency. Companies are investing in advanced machinery and automation to enhance production capabilities, reduce lead times, and improve overall product performance. Sustainability has also become a significant focus, with many firms exploring eco-friendly practices and materials to minimize waste and environmental impact.

With the ongoing evolution of technologies such as 5G, IoT, and AI, the PCB fabrication industry is set to expand further, requiring manufacturers to be agile and responsive to market demands.

When selecting a PCB fabrication company for your next project, it's crucial to consider several key criteria that can influence the success of your design and manufacturing process. One of the primary factors is the company's manufacturing capabilities. A robust PCB fab should offer diverse manufacturing techniques, including advanced technologies like HDI (High-Density Interconnect) and RF (Radio Frequency) PCB capabilities. According to a report by IPC, the global PCB market is projected to grow to $82 billion by 2025, emphasizing the importance of staying updated with advanced fabrication methods.

Another essential consideration is the company's quality assurance processes. Look for manufacturers that adhere to international standards such as ISO 9001 or IPC-A-600, which ensure high-quality production and reliability of PCBs. Additionally, customer reviews and industry reputation can offer insights into their consistency and adherence to deadlines. A survey conducted by the Research and Markets showed that 70% of engineers prioritize a manufacturer's proven track record of quality as a decisive factor when choosing a fabrication partner. Assessing these criteria will not only streamline your project but also enhance the overall performance and reliability of your electronic applications.

When embarking on a new project that involves printed circuit boards (PCBs), selecting the right fabrication partner is crucial for success. The global PCB market has been witnessing robust growth; according to a report by Research and Markets, the PCB industry is projected to reach a value of approximately $83 billion by 2026, growing at a compound annual growth rate (CAGR) of around 3.8%. This growth reflects increasing demands across various sectors, especially in consumer electronics, automotive, and telecommunications.

In choosing a PCB fabrication company, it is essential to consider factors such as production capabilities, technology expertise, and quality assurance processes. The industry is advancing rapidly with innovations such as high-density interconnect (HDI) technology and flexible circuit boards, which require specialized knowledge and equipment. Additionally, a company's commitment to sustainability and eco-friendly practices is becoming increasingly important in today's environmentally-conscious market, as manufacturers strive to minimize waste and streamline supply chains to enhance efficiency. By evaluating these factors and considering a range of reputable fabrication companies, you can ensure a successful collaboration and high-quality outcomes for your electronic projects.

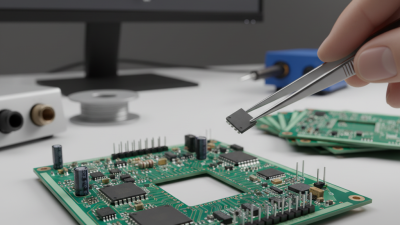

When selecting a PCB fab company for your next project, understanding the key services they offer is crucial to ensure that your specific needs are met. Leading PCB fabricators typically provide a wide array of services, one of the most vital being custom PCB design and prototyping. This allows designers to create tailored solutions that meet the unique requirements of their projects, experimenting with different layouts and specifications before entering mass production.

In addition to design services, top PCB fabricators often specialize in various manufacturing techniques, including multi-layer PCB production, rigid and flexible circuit boards, and advanced material options. This versatility ensures that clients can choose the most suitable technology for their application, whether it's for consumer electronics, automotive, or industrial use. Quality assurance is another cornerstone of PCB fabrication services, with rigorous testing processes implemented throughout production to maintain high standards and reduce the risk of defects. This comprehensive support guarantees that clients receive reliable and effective PCB solutions aligned with their project goals.

Emerging trends in PCB fabrication technology are reshaping the landscape of electronics manufacturing, focusing on enhanced efficiency, miniaturization, and sustainability. One notable trend is the increased integration of AI and machine learning into the design and manufacturing processes. These technologies help optimize production processes by predicting potential failures, minimizing waste, and improving design accuracy. As a result, manufacturers can deliver high-quality PCBs at a lower cost and with faster turnaround times.

Another significant development is the shift towards more sustainable materials and processes. As environmental concerns continue to rise, PCB manufacturers are exploring eco-friendly substrates and lead-free soldering techniques. Innovations in biodegradable materials are also gaining traction, offering alternatives that reduce the overall carbon footprint of electronics.

Additionally, advances in additive manufacturing, such as 3D printing, are providing exciting new possibilities for creating complex PCB structures that were previously challenging to achieve using traditional methods. These trends not only improve the performance and longevity of electronic devices but also align with the global push for greener manufacturing practices.