In the fast-evolving landscape of electronics, the selection of the right print PCB board is a critical step that can greatly influence overall project success. According to a recent industry report by IPC, the global PCB market is projected to reach $80 billion by 2025, highlighting the rising demand for innovative and efficient design solutions. With an increasing number of devices requiring tailored circuit boards, understanding the nuances of print PCB board selection has never been more vital for engineers and project managers alike.

Choosing the optimal print PCB board entails careful consideration of various factors, including material types, manufacturing processes, and design specifications. A survey conducted by Deloitte found that 71% of companies are now prioritizing customized PCB solutions to enhance product performance and reliability. This trend underscores the importance of leveraging expertise in material properties and design techniques when selecting a print PCB board to ensure that it meets both functional and regulatory requirements. With the right insights and strategies, projects can achieve improved durability, efficiency, and cost-effectiveness in PCB implementation.

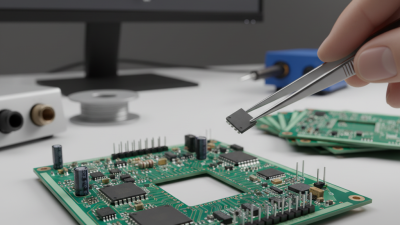

When embarking on a project that requires a printed circuit board (PCB), understanding the various types of PCB boards available is crucial for optimal results. The most common types include single-sided, double-sided, and multi-layer PCBs. A single-sided PCB, with components on one side and traces on the other, is a cost-effective choice for simple designs. According to a 2021 report from the IPC (Institute for Printed Circuits), single-sided boards account for nearly 30% of the overall PCB market, primarily due to their simplicity in manufacturing and assembly.

Double-sided PCBs allow for more complex circuits by utilizing both sides of the board for components and traces. Multi-layer PCBs, which can consist of several layers of circuit boards stacked together, are the go-to for advanced applications requiring high-density connections, such as smartphones and high-performance computing devices.

Recent insights from a market research study predict that the global multi-layer PCB market will grow significantly, with a projected CAGR of 8.52% from 2023 to 2028. This growth reflects the increasing demand for more sophisticated electronic devices that require robust and compact circuit solutions. Understanding these different types can help engineers make informed decisions tailored to the specific needs of their projects.

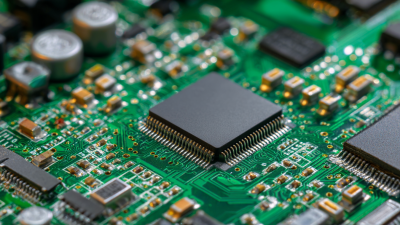

When selecting the right PCB material for your project, several key factors should be prioritized to ensure performance and reliability. First, consider the application and operating conditions of the PCB. Different materials exhibit various thermal, mechanical, and electrical properties, which can greatly affect the performance. For instance, high-frequency applications may require materials with low dielectric loss, while applications in harsh environments may necessitate materials with superior thermal and chemical resistance.

Another critical factor is the PCB's size and complexity. With the trend toward miniaturization in the electronics industry, selecting lightweight and compact materials is essential for enhancing efficiency and reliability. The material's manufacturing processes and its compatibility with the design techniques also play a significant role. Moreover, as the automotive and AI industries grow, the demand for high-speed and advanced PCBs increases, making it vital to choose materials that can support high-density interconnects while maintaining signal integrity. Balancing these considerations will ultimately lead to a more robust and effective PCB design.

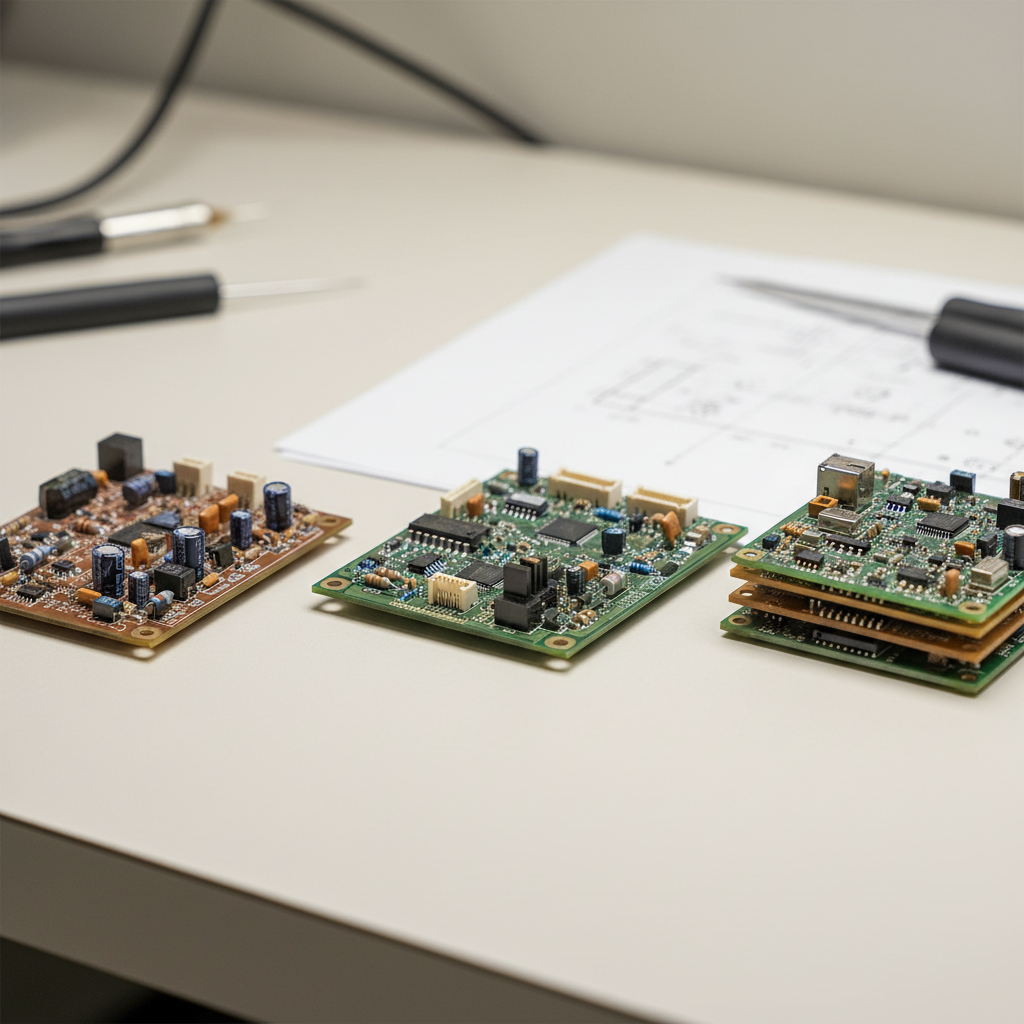

When selecting a print PCB board for your project, one of the crucial factors to consider is the layer count. The number of layers in a PCB can significantly impact its performance and complexity. According to a market research report by Allied Market Research, multi-layer PCBs are increasingly favored in complex applications, with the global multi-layer PCB market projected to reach $39.7 billion by 2025. More layers allow for tighter routing, increased component density, and enhanced signal integrity, making them essential for high-frequency applications which require reliable performance.

In evaluating layer count, it’s important to understand how it influences design capabilities. While a simpler, two-layer PCB may suffice for basic applications, more intricate designs typically require four or more layers to efficiently handle the necessary connections. Tips for choosing the right PCB include assessing your project’s electrical performance requirements, thermal management needs, and space constraints. As designs evolve towards miniaturization, opting for a higher layer count can often streamline connectivity, helping to avoid common pitfalls such as interference and crosstalk.

Additionally, while higher-layer PCBs offer increased capabilities, they also come with higher manufacturing costs and complexity. An effective strategy is to balance these costs against the performance benefits, which can be achieved by consulting with board manufacturers and leveraging their expertise in PCB design. Taking into account the relationship between layer count and overall project goals can lead to more efficient and successful outcomes in your PCB development.

When selecting a print PCB board for your project, the importance of circuit design compatibility cannot be overstated. A well-designed circuit lays the foundation for the performance and reliability of the PCB. According to a report by Research and Markets, approximately 30% of electronic project delays are attributed to compatibility issues stemming from poor PCB design choices. Ensuring that your PCB aligns with your circuit design specifications can save both time and resources, leading to a smoother development process and enhanced product performance.

To facilitate a better PCB selection process, consider the following tips: first, meticulously review the electrical specifications of your circuit design. Match the required voltage, current capacities, and frequency characteristics with those offered by the PCB. Next, pay careful attention to the PCB material—materials like FR-4 are typically chosen for their balance of performance and cost, but more specialized applications may require alternatives such as Rogers or Polyimide for improved thermal management or signal integrity. Lastly, don’t overlook the layout; ensure that component placement and routing are optimized for your specific circuit to reduce interference and signal loss.

Remember, investing time in understanding circuit design compatibility can lead to significant improvements in your final product. Keeping in mind the right material selection and layout optimization can minimize costly changes later in the development cycle.

| Tip Number | Tip Description | Considerations | Impact on Compatibility |

|---|---|---|---|

| 1 | Determine the circuit requirements | Voltage, Current, Frequency | Ensures PCB can handle specs |

| 2 | Select the appropriate size | Dimensions suitable for housing | Fits in designated space |

| 3 | Evaluate material types | FR-4, CEM-1, Aluminum | Influences durability and heat dissipation |

| 4 | Check for multilayer capabilities | Complex designs require multiple layers | Supports intricate circuit designs |

| 5 | Review trace width and spacing | Meets current carrying requirements | Ensures signal integrity |

| 6 | Assess solder mask options | Variety in colors and finishes | Affects aesthetics and functionality |

| 7 | Consider surface finish options | HASL, ENIG, OSP | Impacts solderability and corrosion resistance |

| 8 | Plan for thermal management | Heat sinks, vias for heat dissipation | Prevents heat-related issues |

| 9 | Assess impedance control | Critical for high-speed applications | Maintains signal fidelity |

| 10 | Review manufacturer capabilities | Technical support, production capacity | Ensures project success |

When selecting the best printed circuit board (PCB) for your project, the cost versus quality dilemma is paramount. Understanding your project's specific needs is crucial in making an informed choice. High-quality PCBs may come with a higher initial price, but they can significantly reduce long-term costs by minimizing failures and maximizing efficiency. Researching the latest industry trends can also provide insights into the prevailing costs associated with PCB manufacturing, ensuring you get the best value for money.

One key tip for choosing the right PCB is to thoroughly evaluate the manufacturing process. Consider the materials used and the technology employed in production, as these factors will affect both performance and reliability. Another vital point is to review the design software available for your PCB project. Access to tried and tested software tools can enhance not just your design efficiency, but also the overall quality of the final product. Balancing these aspects will facilitate a well-informed decision, enabling you to navigate the intricate landscape of PCB requirements successfully.