The cable harness assembly industry is poised for significant transformation by 2025, driven by advancements in technology and evolving market demands. As the global market is projected to reach approximately $16 billion by 2025, with a compound annual growth rate (CAGR) of over 5%, it underscores the increasing reliance on cable harnesses across various sectors, including automotive, aerospace, and consumer electronics. This growth is propelled by the rising complexity of electronic systems and the demand for efficient, reliable interconnections that can withstand harsher operational conditions.

With emerging trends such as automation, the integration of smart technologies, and a strong push towards sustainable manufacturing practices, the cable harness assembly sector is adapting to meet these challenges. Industry reports indicate that advancements in materials science, such as the use of lightweight and high-strength materials, along with innovative assembly techniques, are critical in addressing the need for enhanced performance and reliability. Furthermore, the focus on customization to cater to specific application requirements is becoming increasingly vital as businesses aim to optimize their production processes and reduce operational costs.

As we explore the top trends in cable harness assembly for 2025, it is essential to recognize how these developments will not only impact the efficiency and effectiveness of production but also define the future landscape of the industry as a whole.

As we approach 2025, the cable harness assembly industry is on the cusp of significant transformations driven by emerging technologies. One of the most compelling trends is the integration of automation and robotics within assembly processes. According to a recent report by MarketsandMarkets, the global market for automated assembly systems is expected to grow at a CAGR of 10.5%, driven by the demand for enhanced precision and efficiency. Automated cable harness assembly not only reduces assembly time but also minimizes human error, allowing manufacturers to consistently achieve high-quality standards.

In addition to automation, the advent of artificial intelligence (AI) and machine learning is set to revolutionize cable harness assembly. These technologies can analyze vast amounts of data from production processes, enabling predictive maintenance and optimizing workflow efficiency. A study from McKinsey indicates that companies implementing AI solutions could see productivity increases of 20-30%. Furthermore, smart sensors embedded within assembly lines can provide real-time monitoring and diagnostics, allowing for immediate corrective actions to be taken, significantly reducing downtime.

Tips: To stay ahead in cable harness assembly, consider investing in training programs for employees to adapt to new technologies. This knowledge will ensure that your workforce is prepared for the seamless integration of automation and AI. Additionally, staying informed about industry trends through professional associations can provide vital insights into best practices and emerging technologies, keeping your operations competitive.

As the cable harness manufacturing industry evolves, sustainability has taken center stage, shaping design, production processes, and materials. A recent report by MarketsandMarkets indicates that the global market for eco-friendly cable harness solutions is expected to witness a compound annual growth rate (CAGR) of over 7% through 2025. This shift is largely driven by increasing regulatory pressures and consumer demand for greener products, pushing manufacturers to adopt environmentally responsible practices.

One prominent trend is the use of recyclable and biodegradable materials in cable harness assembly. According to a study conducted by Research and Markets, approximately 40% of manufacturers are investing in new composite materials that not only enhance performance but also minimize the environmental footprint. This proactive approach not only addresses waste management concerns but also aligns with global initiatives aimed at reducing plastic usage and enhancing circular economy practices.

In addition to materials, the integration of energy-efficient manufacturing technologies is a crucial focus area. The International Energy Agency reports that implementing energy-efficient strategies in production processes can reduce energy consumption by up to 30%. These strategies include automation and the adoption of smart manufacturing techniques, which not only streamline operations but also contribute to lower emissions, thus fostering a more sustainable approach to cable harness assembly in the years to come.

| Trend | Description | Impact on Manufacturing | Expected Growth (%) |

|---|---|---|---|

| Eco-friendly Materials | Increased use of biodegradable and recyclable materials in cable harnesses. | Reduces environmental footprint and meets regulatory requirements. | 25% |

| Automated Assembly | Utilization of robotics and AI in the assembly process to increase efficiency. | Lower labor costs and reduced assembly time. | 30% |

| Custom Solutions | Increasing demand for tailor-made solutions that meet specific client needs. | Enhances customer satisfaction and strengthens competitive advantage. | 20% |

| Integration with Smart Technologies | Incorporating IoT and data analytics into cable harness systems for better monitoring. | Improves performance tracking and predictive maintenance. | 35% |

| Supply Chain Sustainability | Focus on sustainable practices throughout the supply chain. | Enhances brand reputation and regulatory compliance. | 18% |

As we look ahead to 2025, the integration of automation and robotics in cable harness assembly processes is poised to reshape the industry landscape. A recent industry report suggests that the global market for automated assembly solutions is anticipated to grow at a CAGR of 8.5%, driven by the need for increased efficiency and precision. Robotics, particularly in the form of collaborative robots (cobots), are becoming essential in high-volume production environments, allowing for enhanced quality control and reduced error rates.

Incorporating automation within cable harness assembly not only streamlines the manufacturing process but also addresses the skilled labor shortage currently facing the industry. For instance, companies can achieve a 30% reduction in labor costs and a significant decrease in assembly time by adopting automated solutions. As processes become more digitized, the data collected can further inform production capabilities and optimize workflows in real-time.

Tips: When exploring automation options, consider starting with pilot projects to evaluate ROI before a full-scale implementation. Additionally, investing in training for your team on new technologies ensures that they are equipped to work alongside automated systems, maximizing productivity and operational effectiveness. Embracing these changes early can establish a competitive edge in the rapidly evolving cable harness assembly market.

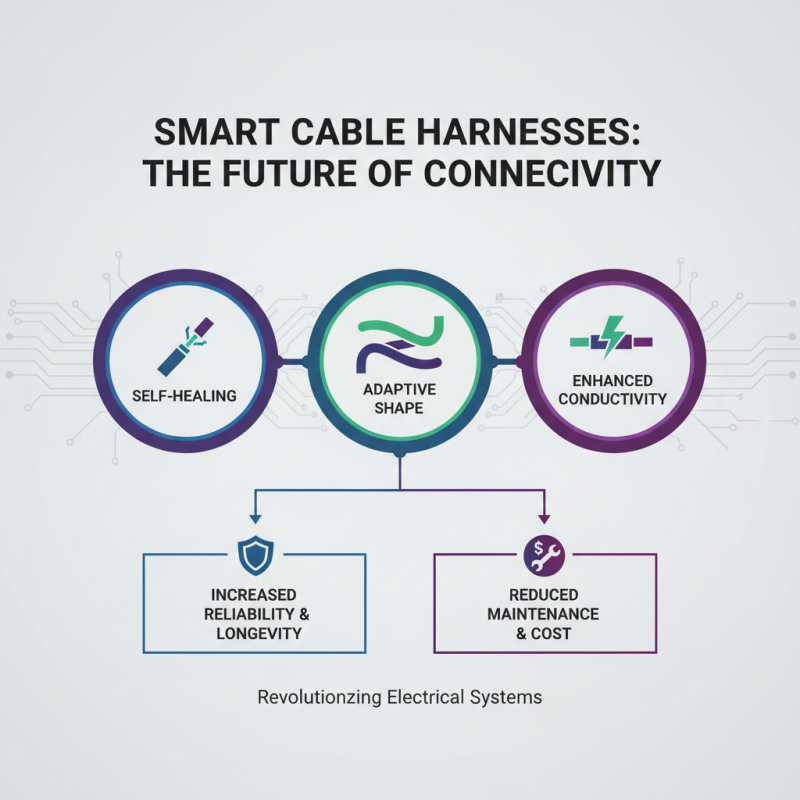

The integration of smart materials into cable harness design is set to revolutionize the way we approach electrical connectivity. These advanced materials can respond dynamically to environmental changes, featuring properties such as self-healing, adaptive shape, and enhanced conductivity. As industries increasingly demand more reliable and efficient systems, incorporating smart materials allows for cable harnesses that not only perform better but also offer longevity and reduced maintenance costs.

Additionally, smart materials contribute significantly to the miniaturization of cable assemblies. By utilizing materials that can adjust their properties under varying conditions, engineers can design more compact harnesses without sacrificing performance. This trend aligns with the ongoing demand for lightweight and space-efficient solutions in sectors such as aerospace, automotive, and consumer electronics. The use of such materials enables the possibility of creating assemblies that can withstand harsher environments while maintaining flexibility and durability, thus better meeting the needs of future technologies.

The demand for innovative cable harness solutions is steadily growing, driven by advancements in technology and evolving market needs. According to a report from MarketsandMarkets, the global cable assembly market is projected to reach approximately $200 billion by 2025, highlighting the importance of cable harness innovations in various sectors, including automotive, aerospace, and telecommunications. Increased automation and the proliferation of smart devices are pushing manufacturers to adopt more complex cable harnessing techniques that offer better performance, reliability, and efficiency.

One of the key market demands influencing these innovations is the necessity for lightweight and compact designs. As industries aim to reduce energy consumption and improve sustainability, the focus has shifted towards materials that offer both strength and lightweight properties. A report by Research and Markets indicates that the use of advanced materials such as carbon fiber and specialized polymers in cable harnesses is expected to surge by over 30% in the next few years. Additionally, the integration of smart technology into cable harness systems, enabling real-time monitoring and diagnostics, is becoming increasingly critical in sectors where safety and performance are paramount.

Furthermore, the push for enhanced connectivity through the Internet of Things (IoT) is another driving force behind the innovation in cable harness solutions. ABI Research predicts that by 2025, over 20 billion IoT devices will be in use globally, requiring robust cable harnessing solutions that can handle the increased data flow and connectivity needs. As a result, manufacturers are investing in the development of custom cable assemblies that cater specifically to the demands of IoT applications, contouring the future landscape of cable harness assembly technology.