In the world of electronics, understanding the intricacies of PCB parts is paramount for anyone looking to undertake electronic projects. Printed Circuit Boards (PCBs) serve as the backbone of virtually all electronic devices, providing the necessary infrastructure to connect components and facilitate the flow of electricity. A comprehensive grasp of PCB parts not only enhances the reliability of your projects but also empowers you to make informed decisions regarding component selection and circuit design.

Moreover, as modern electronics continue to evolve and become more complex, the significance of familiarizing yourself with various PCB parts cannot be overstated. From resistors and capacitors to integrated circuits and connectors, each component plays a crucial role in the overall functionality of the circuit. This understanding will not only aid in troubleshooting and debugging but also foster a greater appreciation for the engineering behind electronic devices. Ultimately, mastering the fundamentals of PCB parts is essential for elevating your electronic projects from basic constructions to innovative creations.

Understanding the importance of PCB parts in electronics design is crucial for anyone embarking on an electronic project.

Printed Circuit Boards (PCBs) serve as the backbone of electronic devices, providing essential pathways for electrical signals and ensuring proper connectivity between components. Each part, from resistors and capacitors to integrated circuits, plays a vital role in determining the performance, reliability, and efficiency of the final product. A thorough grasp of these components allows designers to make informed choices about their specifications, leading to optimized designs that meet both functional and regulatory requirements.

Moreover, a solid understanding of PCB parts contributes to effective troubleshooting and maintenance. When issues arise in an electronic system, knowing how each component interacts within the circuit can dramatically speed up the diagnostic process. This insight not only enhances the ability to innovate but also fosters better collaboration among team members, as a shared knowledge base facilitates communication regarding design intentions and potential challenges.

Therefore, investing time in learning about PCB parts not only improves the quality of electronic designs but also cultivates a deeper appreciation for the complexities involved in modern electronics.

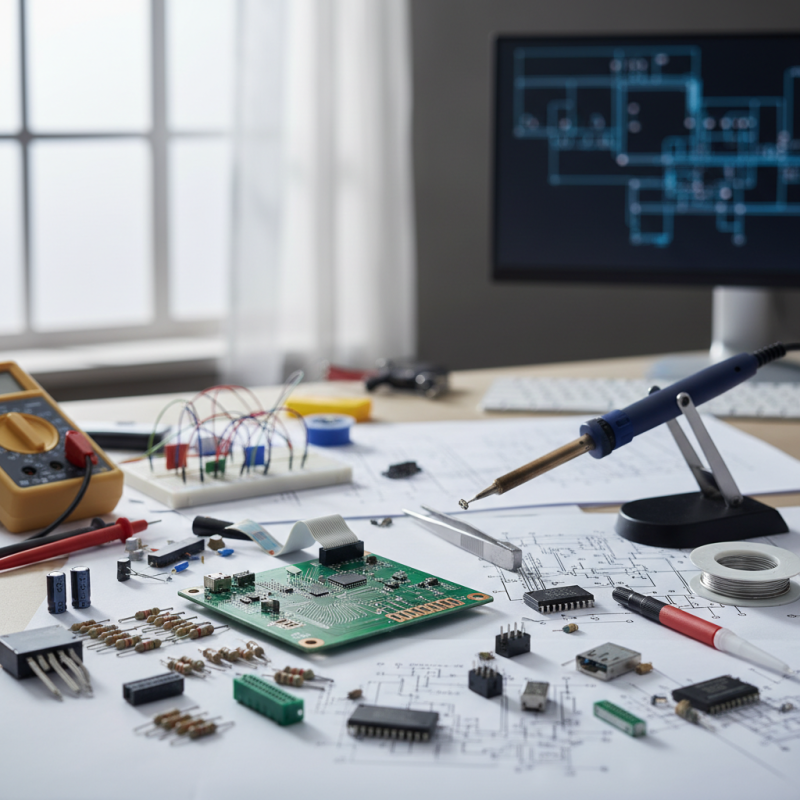

Understanding the key components of printed circuit boards (PCBs) is fundamental for anyone involved in electronic projects. Among the essential elements are capacitors, resistors, and inductors, each playing a distinct role in circuits.

Capacitors store and release electrical energy, allowing for smooth voltage fluctuations and filtering noise, which is crucial in stabilizing power supply and enhancing signal quality. In various applications, they help maintain charge, smoothing out signals for clearer outputs.

Resistors, on the other hand, are fundamental for controlling current flow within a circuit. They create a specific amount of resistance, ensuring that components receive appropriate voltages and currents. By calculating the right resistance values, designers can prevent damage to sensitive components, enabling reliable circuit operation. Inductors function similarly, but they store energy in a magnetic field when current flows through them. They are often used in filtering applications and help manage electromagnetic interference, making them vital for circuit integrity and performance. Understanding these components enhances not only the design process but also troubleshooting and optimizing electronic projects.

The layout of a printed circuit board (PCB) is vital for achieving optimal circuit performance in electronic projects.

As per industry reports, over 70% of PCB-related failures can be attributed to poor layout design choices.

The arrangement of components and the design of traces directly influence signal integrity, electromagnetic interference (EMI), and thermal management.

Configuring the layout with adequate spacing and strategic routing can significantly reduce cross-talk between traces, resulting in a cleaner signal and improved overall functionality.

Moreover, effective PCB layout enhances power distribution, minimizing voltage drop and ensuring efficient operation of components.

A study published by IPC (Association Connecting Electronics Industries) noted that proper power and ground plane management can reduce noise levels by up to

20%, thereby boosting reliability and performance in high-speed applications.

Additionally, integrating design rules such as maintaining uniform trace widths and careful layer stacking can mitigate issues arising from thermal expansion and contraction,

further contributing to the longevity and stability of electronic devices.

Emphasizing the importance of PCB layout not only leads to improved circuit performance but also paves the way for innovation and creativity in product development

within the electronics industry.

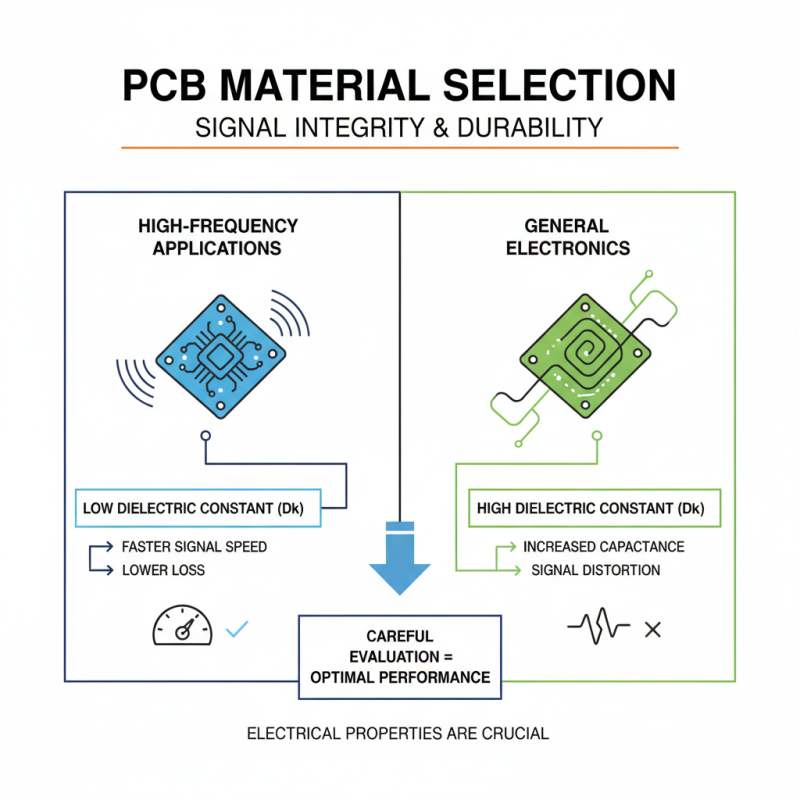

The selection of PCB materials plays a critical role in determining both signal integrity and durability in electronic projects. Different materials exhibit varying electrical properties, which can significantly affect the performance of the circuit. For instance, materials with lower dielectric constants provide better signal speed and lower loss, making them ideal for high-frequency applications. Conversely, choosing materials with a higher dielectric constant might lead to increased capacitance, potentially distorting signal integrity. Therefore, a careful evaluation of material properties is essential to ensure optimal performance.

Durability is another crucial aspect influenced by PCB material selection. Certain materials offer better heat resistance and moisture protection, enhancing the longevity of the PCB in challenging environments. For applications prone to thermal cycling or exposure to harsh chemicals, selecting a robust substrate can prevent delamination or other forms of physical degradation. For engineers and designers, understanding these material characteristics not only helps in creating reliable and efficient electronic devices but also in avoiding costly failures in the long run. Ultimately, informed material choice enhances both the performance and lifespan of electronic projects, making it an integral part of PCB design.

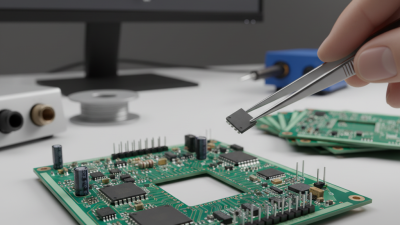

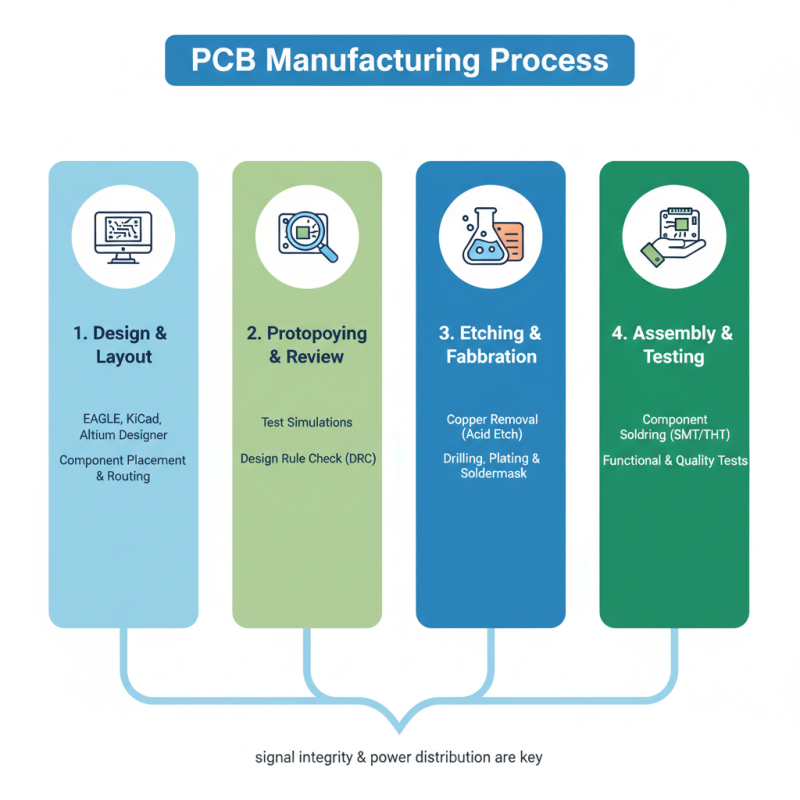

Understanding the common PCB manufacturing processes is crucial for anyone involved in electronic projects. The manufacturing process typically starts with designing the PCB layout using specialized software, which defines the placement of components and routing of connections. Once the design is finalized, the next step involves etching the copper layers to create the circuit pathways. This process can significantly affect the performance of the final product, including factors like signal integrity and power distribution.

Tip: Always double-check your PCB layout design for potential errors before proceeding to manufacturing. A small mistake can lead to costly revisions and delays.

Another key manufacturing method is the drilling process, which creates holes for component leads and vias. The precision of this process can impact the assembly of components and overall reliability of the PCB. After drilling, the boards are usually subjected to surface finishing processes that protect the copper pads and improve solderability.

Tip: Consider the type of surface finish you choose, as it can influence the soldering process and the longevity of your electronic project. Opting for a finish like ENIG (Electroless Nickel Immersion Gold) can offer better performance in many applications.